No compromises with INOTECTM technology

ASK Chemicals stages its leading inorganic binder technology, perfectly suitable for production of aluminum cylinder heads and crankcases by low pressure die casting processes, at the Metal + Metallurgy China trade show in Shanghai from June 13 to 16 in Hall N1 at Booth A27. Thanks to ASK Chemicals’ intensive research in the field of inorganic binder systems, the often-cited technology gap between organic and inorganic binder systems has been closed now. Especially in its key domain of highly productive and high quality automotive aluminum die casting, INOTECTM dominates conventional technologies.

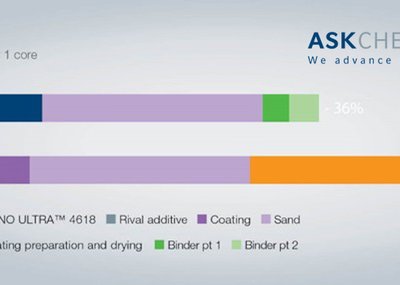

Weaknesses regarding dimensional accuracy, brittleness of cores, and moisture instability or reclamation of used sand have been solved and qualified multiple times on a serial process scale. By contrast, the INOTECTM technology offers significant technological advantages for the foundry industry, including a considerable reduction of sand adhesion (Fig. 1) and penetration, and excellent dimensional accuracy during casting.

Especially the improved structural properties of the aluminum casting, due to shorter dendrite arm spacing, are one of the most striking benefits INOTECTM offers. INOTECTM shows shorter solidification times of the aluminum melt, which directly influences the dendrite arm spacing and thus the structural quality of the casting. ASK Chemicals demonstrated in detailed lab tests that the SDAS values of the casting from the PUCB-bonded mold range from 79 μm to 99 μm, while those obtained for the casting from the INOTECTM-bonded mold are in a range from 66 μm to 86 μm. On average, the SDAS values observed in the casting from the INOTECTM-bonded mold are approximately 9.8% lower.

A modular system to suit specific needs

The INOTECTM technology is a modular system for variable and complex casting geometries. It is perfectly suitable for the adjustment of sand core characteristics depending on the type and geometry of the core. For this purpose, different INOTECTM binder system components with specific properties are used in a defined mixing ratio in order to meet the specific requirements of the respective sand cores with a moderate material consumption. “This modular system offers foundries the flexibility they need in order to produce inorganic core packages with very filigree – and simple or less filigree – geometries,” states Dr. Christian Appelt, Global Incubator Business Manager Inorganics. “Port cores or water jacket cores may require a different blend due to different aluminum-sand ratios and thermal strain differences.”

Unbeatable environmental advantages

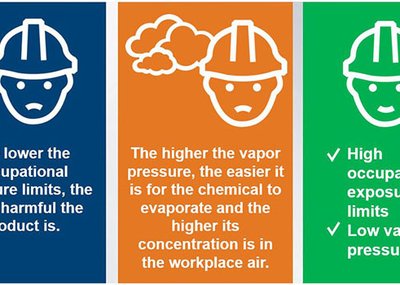

The environmental benefit of INOTECTM relies on the inorganic and water-based nature of this binder technology. The lack of harmful emissions during core manufacturing, core storage, and pouring makes the need for elaborate ventilation and air treatment systems unnecessary (or superfluous) in the process chain. A comparative environmental lifecycle assessment between the INOTECTM system and a Cold Box system showed the best possible result for the INOTECTM technology.

Adding economic benefits

In addition to technological benefits, the INOTECTM technology has clear process-related advantages compared to conventional binder technologies. Particularly notable is the significant increase in productivity of the casting process due to lower permanent mold temperatures enabled by the lack of condensate formation and the resulting shorter solidification times.

A drastic reduction in the consumption of resources for maintenance and servicing work is mainly achieved by the absence of organic components. The use of the INOTECTM system does not result in the buildup of condensate, which in turn reduces the amount of cleaning involved. Investment in air treatment measures is also saved, making INOTECTM a cost-effective alternative in the long term.

ASK Chemicals Casting Academy

On June 14, 2017, ASK Chemicals will be hosting an open ASK Chemicals Casting Academy featuring lectures on its key solutions and leading technologies. A special session is dedicated and handling INOTECTM. Foundries that are interested in joining the ASK Casting Academy, are cordially invited to participate. Further information could be received on the ASK Chemicals booth, Hall N1, booth A27.

Partner

Foundry Corporate News

ASK Chemicals showcases at Metal + Metallurgy China 2017

Reading time: min

[1]