The use of these thermosetting, inorganic binder systems in high-volume automotive applications prevents emissions during core production , core storage and casting. In addition, the value chain in aluminum low-pressure die casting and gravity casting processes can make use of its economic and technological advantages, as no condensates are produced from the pyrolysis of the binder system. This generates additional degrees of freedom for temperature control in the casting process. The faster solidification can result in cast aluminum components with improved metal microstructure. In addition, cleaning and maintenance requirements for the permanent molds are reduced, increasing mold availability and thus productivity.

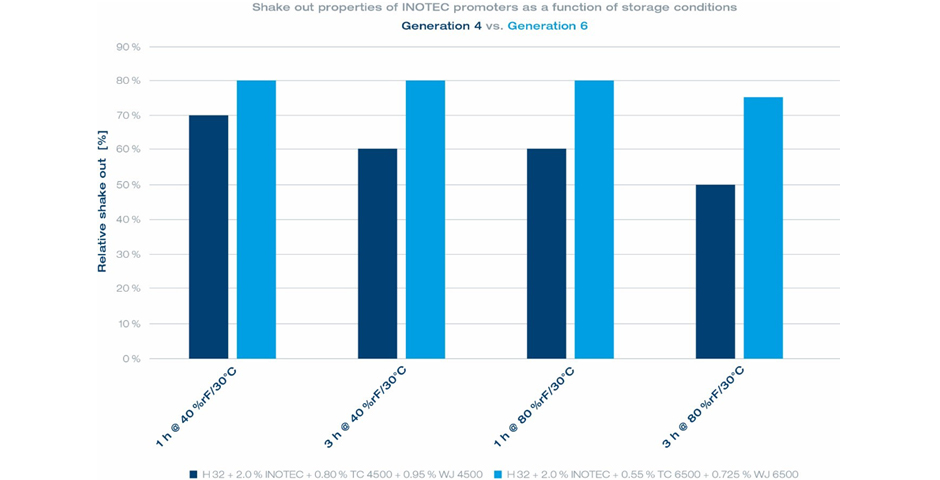

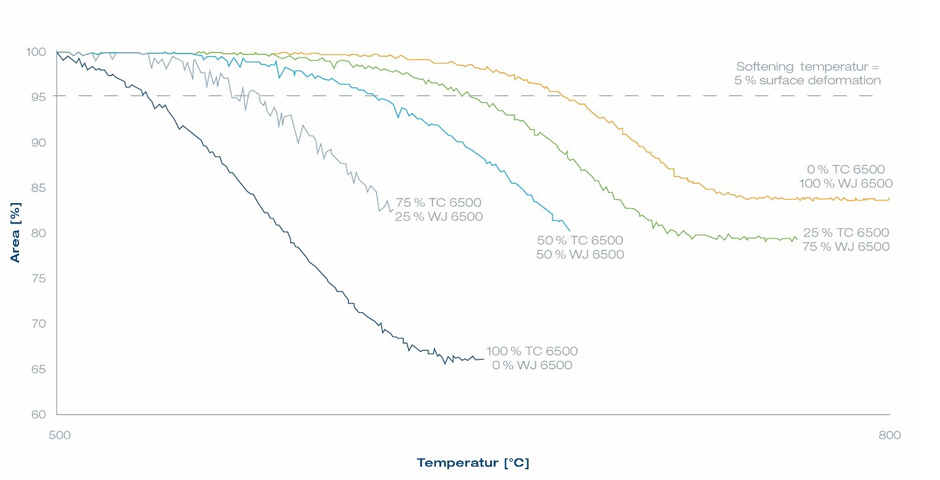

Until now, inorganic binder systems have been used mainly for the production of cylinder heads and crankcases for internal combustion engines. In the course of the diversification of the powertrain in the automotive industry, new fields of application have emerged, so that today central housings for electric motors and structural components (subframes, axle carriers) are also produced with the use of inorganic binder systems. INOTEC technology has thus evolved from a specialty to a diversely applicable binder system in the core production process. Sand core specific properties, such as moisture stability, shake out properties and thermal stability, remain central parameters for the performance profile of inorganic binder systems.

The moisture stability (also called storage stability) of inorganic-bonded sand cores generally describes the stability of the binder system against absolute humidity during core storage. In case of insufficient moisture stability, cracking of the sand core up to core breakage may occur during storage. Uncontrolled absorption of (air) moisture results in an increased gas potential of the inorganic-bonded sand core, so that gas inclusions can remain in the aluminum casting component during the casting processes. After casting, the behavior of the inorganically bonded sand cores with respect to absolute humidity influences the shake out property during raw part processing. If moisture stability is insufficient, reactivation of the binder system can occur and an increase in strength or reduced shake out behavior can be observed. The moisture stability of inorganic binder systems is thus a key performance indicator for the entire process chain of casting production, especially for filigree and complex sand core geometries, such as water jackets for cylinder heads and electric motors. Usually, the moisture stability of inorganic binder systems is controlled by the addition of lithium salts in the liquid binder. However, this results in lower cold strengths as entry value for the core storage, so that comparatively higher addition rates of liquid binder are necessary to obtain a suitable strength level. At the same time, lithium salts in particular cannot be used economically due to the high demand from the battery industry.

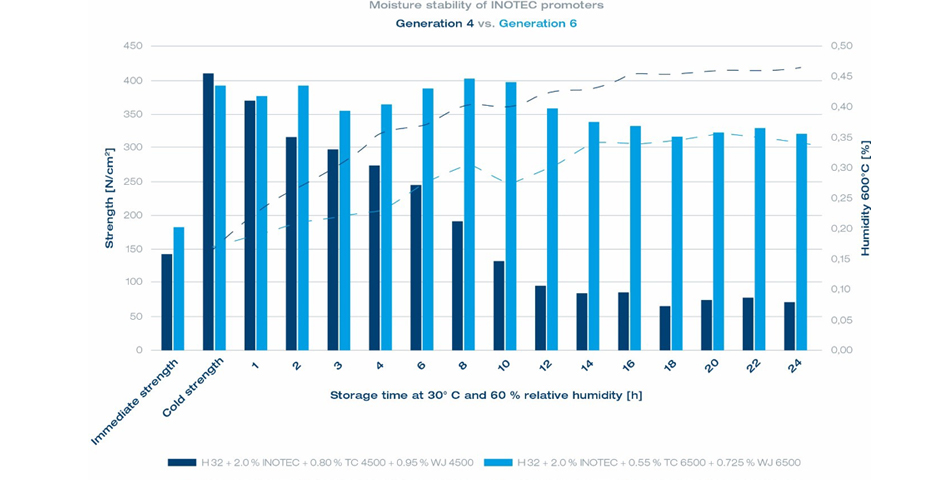

The 6th generation of INOTEC promoters improves the moisture stability of inorganic-bound sand cores as a key performance characteristic of the solid binder system component. The moisture stability of inorganically bonded sand cores can be monitored by determining the strength and moisture content during core storage at high absolute humidity. Measuring the moisture at 600 °C is necessary in order to record the sum of absorbed water in the sand core. Figure 1 shows the development of the two parameters "Strength" (bars and left scale) and "Humidity 600 °C" (dashed lines and right scale) of promoter formulations of the 4th and 6th generation as a function of storage time at an absolute humidity of approx. 18 g water/m3 air (30 °C, 60 % relative humidity).