The reason for this is the increasing demand in the automotive industry for larger and more complex parts. These larger parts require new production processes and are a new challenge for customers. Thanks to its many years of experience with large die-casting solutions, Bühler is your partner for the entire production process for even larger components.

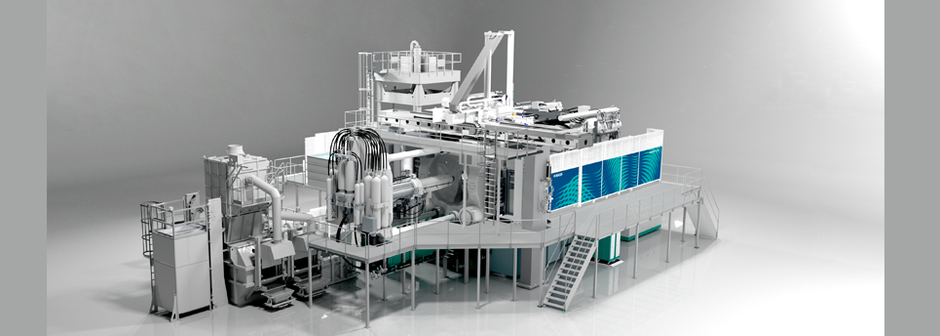

The automobile manufacturers are breaking new ground in their production. Thanks to our Carat series, you can implement your ideas of even larger parts. And we support our customers in developing these new processes, ”says Cornel Mendler, Managing Director Bühler Die Casting. The new Carat 840 and Carat 920 with clamping forces of up to 92,000 kilonewtons (kN) currently round off Bühler's die-casting portfolio. The Carat platform is the company's solution for large die-cast parts. “We are seeing an enormous increase in the demand for ever larger machines. With the Carat 840 and Carat 920, we can offer our customers solutions for large structural components with complex geometries and new body components, ”says Cornel Mendler.

Carat series offers maximum productivity

Bühler's vision for the future of the die casting industry is 0% rejects, 40% less cycle time and 24/7 availability. The larger the cast parts, the greater the leverage for reducing production costs by reducing cycle times, rejects and increasing availability. The design of the Carat 840 and Carat 920 also has a positive effect on the quality of these complex, thin-walled parts. Their manufacture requires an extremely powerful and precise casting unit and a uniform introduction of clamping force.

Carat's two-plate technology has a patented, stiffness-optimized plate design for uniform application of the clamping force, which ensures minimal plate deflection and high dimensional accuracy of the cast parts. In combination with the unique real-time controlled casting unit from Bühler and the DataView control, the Carat offers the highest casting dynamics and quality - shot for shot.

Production close to the customer

Bühler manufactures its die casting platforms in Asia, Europe, and North America. This ensures short delivery times thanks to short transport routes and a reliable supply of spare parts. Customers can rely on a stable global production network. Local service technicians support foundries and automobile manufacturers. Bühler offers fast on-site support or remote maintenance as well as detailed training at the customer's site or in Bühler's application centers.

Exceptional closing forces - comparable to the Eiffel Tower

The largest die casting machines in the Carat series are as big as a house. They are eight meters high and have an area of around 100 square meters. “The Carat 920 can inject more than 200 kilograms of liquid aluminum into a mold within milliseconds. It holds the shape together with a force of 92,000 kN. It is as if the entire Eiffel Tower with its weight of around 9,000 tons was pressed onto the mold, and that with every single shot, ”explains Michael Cinelli, Product Manager Die Casting at Bühler.

First point of contact for solutions with large components

Bühler has been a pioneer in large die-cast parts and the world market leader in this segment for 15 years. Bühler designs and designs total solutions and puts them into operation for customers. Together with its partners, the company can offer process solutions from aluminum bars to finished body parts. The manufacture and handling of such large parts is much more complex than with smaller ones. The upstream and downstream production steps of the die casting cell must also be able to process these parts. Since the components are too big and too heavy to be carried by humans, robots and transport frames form a continuous transport system. They take over the handling from the casting to the body part. “Bühler offers solutions for all of these processes. We have extensive practical knowledge of commissioning and operating such large cells, as we work with foundries all over the world, ”says Michael Cinelli.