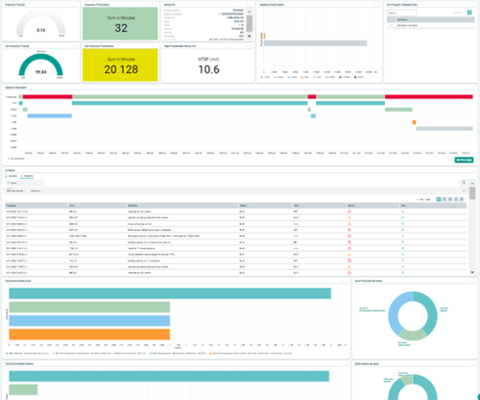

Driving up operational visibility and performance analysis

The benefits of Industry 4.0 continuous, connected data have long been talked about in die casting. Now it’s fully operational across Bühler die-casting cells, with the Die Casting Dashboard that shows production activity at a glance, and Downtime Analysis, which helps to identify the causes of production stoppages.

Die Casting Dashboard provides real-time KPI information

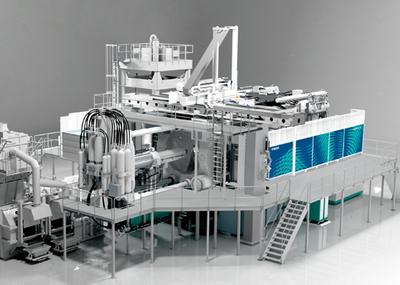

The Die Casting Dashboard, available on Bühler Carat, Evolution and Fusion machines with DataNet or DataView control unit, provides an immediate overview of the production status. Simple displays make it easy to keep an eye on production and plan, manage and improve performance based on real data.

For example, key performance indicators like the cycle time of each die-casting machine are displayed in a logical way, making it easy to monitor and review performance, and anticipate issues.

Downtime Analysis, a comprehensive failure analysis tool, is also available, providing root cause reporting from each die-casting cell.