In 2025, the internationally renowned technology group Heraeus introduced Chameleon Foundry, a newly developed, fully automated temperature measurement system based on fiber-optic technology. With decades of expertise in instrumentation, the company offers a comprehensive portfolio of sensors and accessories for precise control of metallurgical processes – including solutions for measuring temperature, oxygen and carbon content, as well as other quality-critical parameters in foundries.

Precise temperature measurement without disposable sensors for iron foundries

Chameleon Foundry sets new standards in the measurement of molten metal temperatures. Instead of conventional disposable cardboard sensors or traditional thermocouples, the system uses a robust optical fiber for direct measurement in the molten bath. The solution was specifically designed for cast iron foundries and meets the highest requirements in terms of accuracy, reliability, and process safety.

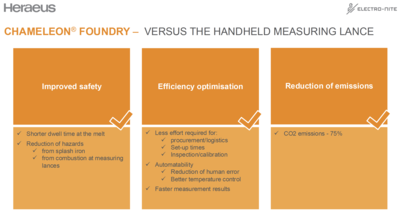

Unlike traditional methods, where operators must manually insert lances into furnaces or ladles, measurements are performed fully automatically and remotely from the control panel. The system autonomously immerses the optical fiber, captures real-time temperature data, and transmits highly precise readings – all without exposing personnel to extreme heat or metal splashes.

Greater efficiency and significant reduction in consumables

Conventional measurement methods using disposable thermocouples involve high material consumption, frequent maintenance, and considerable logistics and storage costs. In addition, they generate substantial waste.

Chameleon Foundry drastically reduces these requirements. A single fiber spool weighing just ten kilograms enables up to 6,000 measurements, replacing several pallets of conventional sensors. This saves storage space, lowers freight costs, and significantly reduces the environmental footprint. Eliminating cardboard tubes means fewer resources consumed, less waste generated, and a meaningful step toward more sustainable foundry operations.

Because fewer components need to be replaced, maintenance efforts are also noticeably reduced, resulting in higher system availability and minimized unplanned downtime.