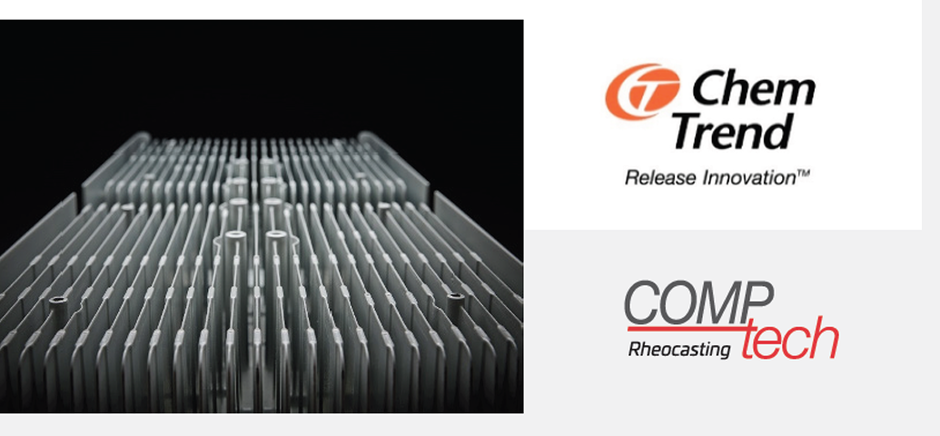

Finding the right kind of lubrication to reach down in these deep pockets with the spray is therefore a key factor why Comptech is happy to announce the development work made with Chem-Trend.

"In order to get all benefits that Rheocasting introduce to both the foundry and the product owner (OEM) it is key that all other disciplines within the diecasting process also deliver. This to ensure that the product owner can get the design required as weil as the foundry gets the benefits of a cost-effective production. Chem-Trend has extensive experience and proprietary technology to deliver advanced die lubricant that offer the best possible performance for each application" Dr. Per Jansson, CEO Comptech Rheocasting AB

"Chem-Trend truly values the opportunity to collaborate with leaders in the field, like Comptech who are designing next-level casting solutions. Comptech's rheocasting system advances the ability to manufacture large, thin-walled and high-strength castings with long flow lengths. Our commercial and technical teams ensure the release agents used within this process provide excellent metal flow characteristics in thin-wall areas, while also optimizing mi crostructure properties essential for high-strength castings. Working alongside Comptech allows us to bring tailorma de die lubricant solutions to OEM's and Tier I suppliers. John J. Belyk, senior business development director die cast, Chem-Trend.

About Comptech Rheocasting

The company develops, produces, and delivers equipment and know-how to the foundry industry and supports designers as OEM's. R&D is a vital role and together with leading R&D institutes we develop alloys with high require ments and alloys with very low C02 footprint. Comptech AB is working on three continents.

About Chem-Trend

Chem-Trend is a global leader in the design, development, and manufacturing of high-performance release agents, purging compounds, paper impregnation chemicals, and other process chemical specialties. Using a custo

mer-centric approach and deep research and development, Chem-Trend is dedicated to improving production efficiency, reducing waste, and minimizing the impact on the environment for its customers.

Founded in 1960 and headquartered in Howell, Michigan, USA Chem-Trend offers a globally integrated network of experienced, knowledgeable, and insightful production and technical experts in all major manufacturing regions

around the world, serving customers through offices in North America, South America, Asia, and Europe. Providing expertise in Brazil since 1986, the company offers state-of-the-art R&D facilities to bring local expertise, product development and support for a wide variety of industries and needs. Chem-Trend is part of Freudenberg Chemical Specialities GmbH, a global technology group.

About Rheocasting

Rheocasting is a semi solid process that delivers melt with a high solid fraction at a low cost. The process is in roll out and is used on three continents with a growing number of installations. Typical components made with the process are leak free components, heat sinks and other thermal management parts, high strength T6 treated components

Vistit Chem-Trend (Deutschland) GmbH at EUROGUSS 2024 at Hall 7A / Booth 7A-110