First-tier auto-industry supplier Rheinmetall Automotive, part of the Rheinmetall Technology Group, has received an order for cooled exhaust-gas recirculation modules from a wellknown German manufacturer of engines for industrial applications and agricultural equipment. The supply contract, which has already been in place for several years, has been extended for another five. It will come into force as early as spring 2020 and is worth a total of just under €110 million.

Through its subsidiary Pierburg, Rheinmetall Automotive will supply complete exhaust gas recirculation modules to the customer's German production site. The components destined for the heavy-duty sector will be installed in various engine models with displacements in excess of four liters. They are intended for industrial applications as well as for agricultural and construction equipment.

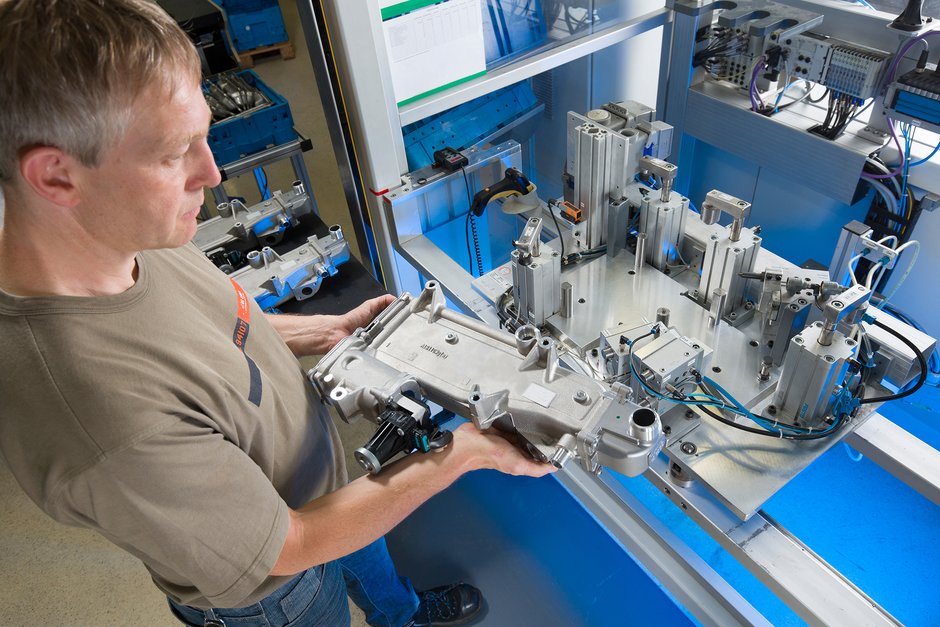

The exhaust gas recirculation modules are manufactured at Pierburg's Lower Rhine plant. As world market leader in EGR systems, the company casts, finishes and assembles the modules entirely at this location at the Neuss pier. In diesel engines, cooled exhaust-gas recirculation can significantly reduce nitrogen oxide emissions and fuel consumption (CO2 emissions) thanks to the higher EGR rates that can be achieved.