"Die casting industry changing - climate protection and the active wait for green hydrogen"

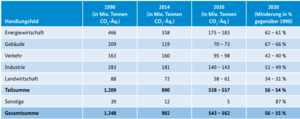

Renewable energies and green hydrogen are currently being discussed as the best way to achieve these ambitious targets. However, the capacities of renewable energies in many parts of the world, Europe and also in Germany are currently not large enough to produce sufficient quantities of green hydrogen using the electrolysis process. Natural hydrogen deposits are rare on our planet and do not offer any guarantee of supply. The Climate Action Plan 2050 [1] contains targets that describe the reduction of greenhouse gas emissions by 2030 (Table 1). According to this, approx. 50% of greenhouse gas emissions (in CO2 eq.) are to be reduced in industry.

How this can be achieved in detail has not yet been specifically outlined. Preparations are being made to make the infrastructure and energy availability possible. However, it remains to be seen whether this will be achieved despite the already known crises and possible new risks. It is not yet possible to confirm when and where green hydrogen will be available. The simplest way to reduce energy and CO2 emissions by 50% would also be to reduce production by 50% and consumption by 50%. However, this idea is in conflict with the desire for prosperity and growth of many people and companies.

The question arises: What can already be done today to reduce greenhouse gas emissions and energy consumption without the availability of green hydrogen?

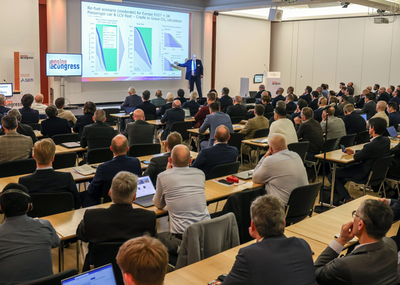

The lecture at the 23rd Die Casting Day [2] in Nuremberg at EUROGUSS 2024 and this article are intended to provide ideas and incentives to deal with the topic and implement energy savings with methods and means available today [3, 4], i.e. even without green hydrogen.

Relocating production and simply waiting are not an option

The following scenarios would not be good for our climate: 1. production is relocated abroad because energy is cheaper there and there is less cost pressure due to climate protection. 2. wait until green hydrogen is available to everyone. In both cases, no improvements for climate protection would be achieved from a global perspective.

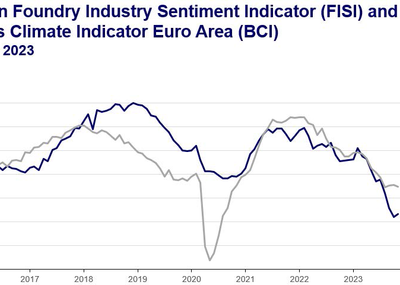

The die casting industry and all other energy-intensive industries in Germany and Europe suffer particularly from high energy costs and climate protection levies. As a result, there is already a need for action today.

In the die casting industry, solid metals are melted until they have the desired characteristics as liquid metal so that they can be molded in die casting machines. These metals are often melted down in fossil-fired melting furnaces. In some cases, the operators of the melting furnaces know the characteristics of their melting process well and are well-informed about their position in terms of energy efficiency, productivity and emissions compared with other melting processes. When this is not the case, a comparison can be an eye-opener. It reveals the current situation and what still needs to be done to achieve the targets set out in the Climate Action Plan 2050.

The melting of solid aluminum takes place during the melting process in a smelting furnace. Benchmarking natural gas-fired smelting furnaces can help to further understand how good the technology used is. The melting process consists of several process steps such as: Charging, melting, superheating, possibly alloying and casting or transfer. From the energy input and the melting rate, characteristic values can be determined which are comparable.

For this comparison of melting processes, it is rarely sufficient to compare the melting furnaces of the own plant with each other and derive measures from this. Rather, it makes sense to look and ask yourself the question: What is being done differently and better elsewhere and how can I, as operator of my own melting furnaces, achieve this? What are the limits of my melting process? To what extent can the process be further improved using conventional methods? Every refitting and every modification costs money, so it is important to act in an informed and forward-looking manner. Every investment should be justified by a profitability analysis.

Summary

The requirements of the Climate Protection Plan 2050 create many tasks and questions for the die casting industry in Germany. The German government leaves no doubt that the targets will be achieved. Higher energy costs and climate taxes are to be expected in the future. The resulting pressure on producers of die-cast parts to act is not an invitation to wait and see. The target of reducing greenhouse gas emissions by around 50% by 2030 can already be achieved with conventional measures to increase energy efficiency. Even without green hydrogen.

A contribution by Dr.-Ing. Thomas Niehoff