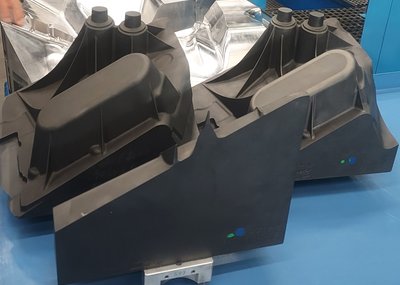

With DuraCool, Schaufler Tooling presents an innovative technology for tool cooling that significantly outperforms existing contour-based solutions. The aim is to optimise heat dissipation in die-casting tools, shorten cycle times and at the same time increase the service life of the tools – and all this at lower costs than with conventional additively manufactured inserts.

Conventional contour-based cooling systems, which are usually manufactured using 3D printing from 1.2709 material, are increasingly reaching their physical and economic limits. The limited thermal conductivity of these materials, combined with their susceptibility to cracking and leaks in the cooling channels, leads to higher maintenance costs and longer cycle times. In addition, the manufacture of such inserts is cost-intensive, which limits their economic viability in series production.

The cooling channels are completely leak-free

This is where DuraCool comes in, combining a stainless steel shell with integrated cooling channels and a specially developed filling material that has four times the thermal conductivity of conventional hot-work steel. This hybrid design enables up to 20 per cent faster heat dissipation, reduces costs by around 30 per cent and doubles the service life of the tools. Thanks to the completely sealed material composite, the cooling channels are absolutely leak-free, while the homogeneous structure eliminates porosity and thermal weak points. The result is a highly stable insert with optimum heat transfer and maximum process reliability.

Initial pilot projects have impressively confirmed the practical suitability of DuraCool. In complex tool geometries, a fully integrated cooling structure has been implemented that delivers stable performance even under series production conditions. In trials, a cycle time reduction of three to five seconds per shot was achieved, accompanied by improved surface quality of the castings and significantly reduced thermal stress on the tool.

A phased roll-out is planned for 2025: following the ongoing development and testing phase in the first half of the year, extensive pilot applications and validations under series production conditions are to follow in the third and fourth quarters. The aim is to launch DuraCool as an economical, robust and sustainable alternative to existing additive cooling concepts.

With this technology, Schaufler is setting new standards in tool and process development. DuraCool stands for higher productivity, improved component quality and a significant reduction in operating costs – a decisive step towards more efficient and sustainable die-casting production.

Further information: www.schaufler.de/en