The competition was also supported by the Federal Association of the German Foundry Industry e.V. (Bundesverband der Deutschen Gießerei-Industrie e.V. - BDG), the General Association of the Aluminum Industry (Gesamtverband der Aluminiumindustrie e.V. - GDA) and the European Magnesium Research Association e.V. (Europäischen Forschungsgemeinschaft Magnesium e.V. - EFM). This competition was intended to demonstrate to the public and customers in particular the diversity of applications, the innovative strength, the high level of quality and the performance of the die-casting process in the materials aluminium, magnesium and zinc.

The competition entries were evaluated individually in the materials and evaluated in terms of innovation, quality, cost-effectiveness, resource-efficient design and level of difficulty. Subsequently, the three best parts for each material will be awarded.

Around 30 die castings were submitted by the end of September 2021 and in mid-January 2022 the winners were honoured in an entertaining and interesting online presentation by Martin Vogt (BDG) and Chris Boss (EUROGUSS).

The most innovative and technically outstanding die-cast products made of the materials aluminium, magnesium and zinc were awarded.

Now the winners have been announced:

See the exhibit and the award winners in the individual categories here:

Winner Category Zinc Die Casting

1st prize: Assembly consisting of three die-cast parts / housing-lid-front, Dipl. Siegfried Müller GmbH & Co. KG

2nd prize: Gearshift handle, automotive interior, HDO Druckguss- u. Oberflächentechnik GmbH*

3rd prize: Clamping plate, Teilemacherei GmbH*

Winners Category Magnesium Die Casting

1st prize: Cross Car Beam HUD / Instrument Cross Beam / Legal Support, GF Casting Solutions Schaffhausen

2nd prize: TKS 80 table top, TORUN Bark Magnesium GmbH*

3rd prize: Cone Holder EE0043-30-2020, Dynacast Deutschland GmbH*

Winner Category Aluminium Die Casting

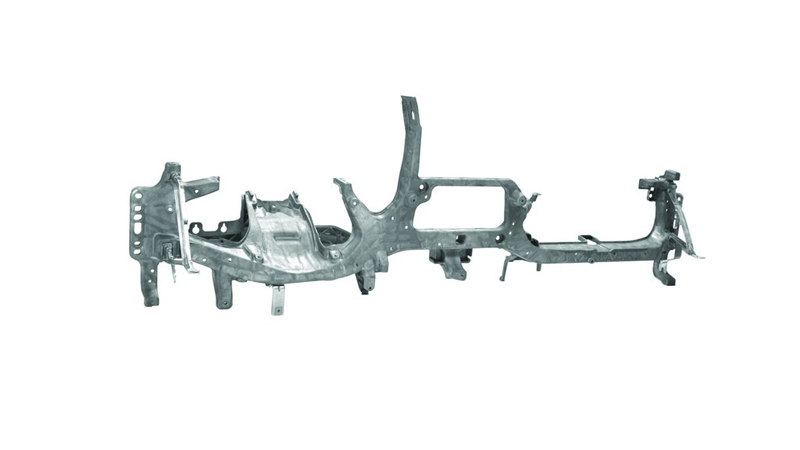

1st prize: One-piece upper shell of a rear axle beam made of die-cast aluminium, Albert Handtmann Metallgusswerk GmbH & Co. KG

2nd prize: System Carrier, Alupress AG Brixen*

2nd prize: SP52 lower housing, BMW AG Landshut plant*

3rd prize: Housing 3498 & 3D-printed sample, Matthies Druckguss GmbH & Co. KG*

*See here to see the 1st place winners in their category and their castings

The photos plus descriptions of the castings of the other winners will follow in Part II here on Foundry-Planet in the next few days.