A New Innovative Casting Process and its Highly Effective Application in the Manufacturing of High-Performance Engine Components from Aluminum Foundry Alloys

Dipl.-Ing. Herbert Sm etan, SMETAN engineering GmbH in Rehlingen-Siersburg/Germany in Cooperation with FILL GmbH in Gurten/Austria and MEISSNER AG in Biedenkopf-Wallau/Germany

similar to “Herbert Smetan, GIESSEREI 1/2014 and Austrian GIESSEREI RUNDSCHAU 61 (2014), Heft 1/2“

Starting Position

The production of cast aluminum cylinder-heads has developed towards commodity business that has already achieved a significant market saturation on the supplier side in the last decade (as aluminum foundries have equally experienced in the past in the case of the similar demanding cast aluminum wheels in the 90s), so that this very clearly has already led to a selection processes within the relevant global industry. At the same time, triggered by the downsizing of engines, the specific power density is steadily increasing in such a manner that much more demanding challenges are placed on the specifications of these components (see Figure 1-3). In addition, due to value analytical considerations by the OEMs, the degree of integration of these components is continuously increasing (see Figure 4). Especially in conjunction with the platform strategies of OEMs, where requested quantities of the derivatives increase worldwide significantly, the scale effects of the market leaders worldwide, have led to a signifi ant rationalization pressure through global pricing. On top of that, the globalization of the automotive business is steadily demanding more "local content" by the emerging economies. In this context, it is quite essential that the applied casting processes for this complex and material- and dimensional-wise extremely sophisticated design elements of lightweight engines are developed as robust as possible, so that a "taking global" of production through a "roll-out" of standardized processes eventually becomes feasible at all.

In this context SMETAN engineering and its partners have under quality-related as well as under productivity-relevant factors unrestrictedly questioned the entire process of die-casting in all its elements, with the aim to make this process significantly more effective. In the present article it is to demonstrate how the process robustness, the quality of the components and productivity of the manufacturing set-up form an inseparable whole that allows the view at it from a completely new perspective, even after centuries in tradition of this industry, which still offers surprising leeway for further improvements (see Herbert Smetan: "Simply being better is enough"; GIESSEREI 9/2009).

Omit - Simplify - Integrate - Automate, that is the order, driven by the lean production-approach to continuous improvements in manufacturing systems. We went within our considerations, however, the decisive step further and compiled at their very beginning the needs of the actual casting process uncompromisingly in the foreground in order to increase the robustness of the casting process to an extent that allows you to attack the above mentioned task from a completely unfamiliar perspective. From this point of view, we identified completely unexpected solutions with completely underestimated effects in the magnitude of their potentials. Not only in operational sequences and work flows we can improve productivity by skillfully omitting steps, also for example, in the filling of a cavity, skillfully omitted steps lead to very significant improvements in the quality and the reliability of cast products. To us aluminum foundry experts, it is very obvious that through any decanting of liquid metal the quality of the liquid metal suffers significantly, but we seem to heavily compromise this principle by our nowadays preferably applied standard casting processes, right at the point in time when we fill the cavity.

In aluminum die casting today, there are basically two approaches dominating the casting methodology, the gravity-die-casting-process as well as the low-pressure-die casting-process. Since there seems to be besides the very obvious advantages some disadvantages involved in both methods, dynamic casting processes were emerging, which often became only reliably feasible by modern mechanical equipment and cybernetics.

A new dynamic casting method with considerable leeway for further efficiency gains based on exemplary process robustness:

The approach, in the actual article presented, is based on the long term proven approach of the tilt-castingprocess with a firmly attached basin to the mold. Only that in the actual case, the basin can be released from the mold and gently filled by a robot with extremely low turbulences from a bail-out-furnace. Once this basin is then connected to the mold again and undocked from the robot, by controlled rotational movement, the cavity of the die begins to fill (see Figure 5). The total rotation angle as well as the rotation speed itself can be freely determined within a wide range. After the filling of the cavity, the robot removes the basin again from the mold and moves to a waiting position above the bail-out-furnace for the subsequent casting cycle. Thus, for the extraction of the casting, the cleaning of the die and the setting of the core-assembly the tooling is completely accessible from all sides (see Figure 6).

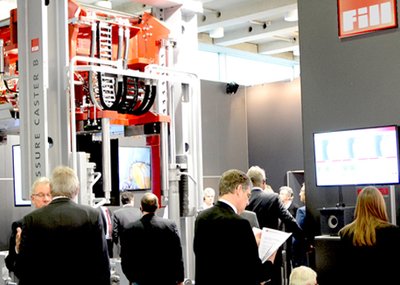

A new and innovative manufacturing layout containing further rationalization potentials and a jobbingfoundry-friendly flexibility: given the extremely short mold-filling- and solidification-cycle, the individual tiltcasting-benches are arranged on 3-station-carousels and two carousels are joint together to a TwinCarouselLine. By this, the robots for pouring, the extraction of the castings and the setting of cores as well as further peripheral equipment are fully utilized. As a consequence of this arrangement the downstream equipment for de-coring and sawing is running on its technically maximum throughput too (see Figure 7). The arrangement of 3 benches on a carousel allows jobbing-foundries maximal flexibility in the utilization of their installed capacities in combination with obvious advantages with regard to operation: the supply of cores and liquid metal on the one hand and the removal of castings on the other hand. Such an arrangement has already been implemented by the above-mentioned cooperation for a Turkish jobbing-foundry to manufacture a highly complex cylinder-head of the newest design for a German OEM. This component was managed to be validated as a first product in the newly developed dynamic-tilt-casting-process in an extremely short project-time. The present article is concerned as well with the theoretical as well as with the industrial relevance of this approach. During several years of scientific evaluations, this innovative technology and manufacturing-set-up has been defined, which aim it was, to set a new global industry benchmark in productivity as well as with regard to the superiority of the components’ quality.

Technological Aspects

Runner- and gating-systems are, by definition, supporting systems to the genuine pouring process. Even the very best design represents always a compromise with respect to a controlled and regulated, low-turbulence filling of the cavity. In particular, in the starting phase, the system is extremely unstable with respect to turmoil and turbulences. In this situation, also nowadays, the gravity has an influence on the overall system, which in practice, is only controlled to quite a limited extent by the foundry experts. Therefore, very early in foundry history, experts introduced rather simple tilt-casting-processes in particular to alleviate the kinetics in the initial starting-phase of the actual pouring. In our views, attributable to this approach is as well the inclination of molds, which has been preferably utilized for flat, large-scale parts since immemorial days and this across almost all casting processes.

From this endeavor unaffected remains the fact that bottom pouring is preferable for the most controlled and low in turbulence filling of a cavity. But by this approach, the temperature stratification in the casting part itself at the end of the filling represents the exact opposite of what would be desirable for a directed feeding throughout the solidification. Concurrently, the temperature distribution in the tooling itself also represents the opposite to what would be advantageous for a directed solidification and feeding of the component. This sets the conditions for a directed solidification of any component towards the feeder literally on its head.

This situation is not changed by dynamic-casting-processes even a little if conventional runner-systems for bottom-pouring were applied. Even worse, in cases where the robot with the ladle has to follow the very complex tilting-movement of the mold, dynamic-pouring may incorporate some disadvantageous features. Since it already is a most difficult task to ensure an optimal level of the metal in the pouring basin at the top of the down-sprue for different molds of the same component in static processes, this task simultaneously applied to a rotating mold movement becomes almost unsolvable. And this is not a question of the technical cybernetic which is available nowadays. Very often, then ceramic- or even mesh-filters are used in the runner-system for partial compensation of the accompanying symptoms.

As introduced by the author in previous years for the core-packages-system (CPS), the cavity was filled through a feeder with an integrated flow-optimized gating system in gravity-contact-pouring directly from the bottom of a launder. Immediately after the mold filling had been finished, the entire mold was then very quickly turned into the solidification position. Although this approach solved the problem of inverse temperature stratification quite elegant, it still left the problem of the actual mold filling largely untouched (see Herbert Smetan: "Casting processes as the area of conflict of future-oriented lightweight engine designs"; GIESSEREI 11/2006). The filling of the cavity by the means of a laterally docked electromagneticpump represents a potential solution to this problem, at least in a purely theoretical consideration most closely, but could not sustain prevail on the basis of too expensive and most sophisticated equipment for industrial applications.

From this point of our view, the classic tilt-casting-process with a rather flat and firmly docked pouring basin dissolves this task the best, although the descanting of the liquid metal into this basin generally creates oxide-film-formations and causes hydrogen absorption. The geometry of this type of basin also triggers a rapid temperature drop during the waiting times prior the actual start of pouring.

The low-pressure-die-casting-process , which certainly ensures a textbook-like filling of the cavity, contains as a specificity of the process-characteristics that the temperature stratifications in the component and the tooling are also in this case literally put upside down and this fact becomes even more sustainable, promoted by a convection, which arises from the fact that the hot metal from crucible at the bottom of the tube very intensively exchanges itself with the colder metal at the top of the tube at the solidification front of the casting. Extreme long solidification-cycles are the result which is very negatively affecting the productivity of this process. Elaborated cooling technology represents an attempt to realize, despite of the adverse conditions, directed solidification. For purely rotationally symmetrical components like cast aluminum wheels the benefits outweigh these disadvantages yet, so that in these cases, the process has been predominantly established.

It was now the challenge, to find within a variety of potential solutions offered, those which the best potential for further development, containing quality-wise as well as productivity-wise preconditions to define a simple and unified process that provides a robust and reliable solution to the foundries, by capturing all the capabilities of modern tool design and equipment technology. The process-robustness and the process-productivity build an integrative precondition for significant improvements with regard to output and quality. That is why it was particular that two fundamental elements were provided from the selected approach: the pouring basin must be on the one hand firmly attached to the die and on the other hand directly be filled by smooth scooping from a bail-out-furnace. That is the implication why this pouring basin must actually be undocked by a robot from the die to be then gently and free of oxides filled from the bailout-furnace. By this, the die is also completely free and provides unhind red access to operators and robots from all sides, what can be taken as a positive side effect from a manufacturing perspective.

With regard to the basin-geometry, we assumed that the shape of the basin follows the interface to the feeder in its full length along its lower contour in the position prior to the start of the pouring cycle. At the same time, we perceived it as fundamental that the geometry of the interface between basin and the feeder does not have any skimmers or similar upward-limitations like bulkheads, not to impede the free flow of the metal. In general, these bulkheads in other approaches were owed attempts to retain oxides, foam and dross at the bath’s surface that were formed during the actual filling of the basin by the means of a ladle.

In the presented approach the metal enters smoothly through the slot-shaped, perpendicular orifice of the basin when this is gently immersed by the pouring-robot into the liquid metal in the bail-out-furnace. The presented basin-design ensures that only clean and oxide free metal gently flows into the basin. The actual content of liquid aluminum in the basin is then covered and protected among a young, yet elastic oxide skin, which was newly formed on its surface during the smooth filling of the basin. Throughout the entire filling of the cavity this oxide skin remains largely undamaged on the liquid metal’s surface and swaps at the end on the top of the riser. In this context this casting process works entirety without any "down-sprue or runnersystem".

The starting angle for the actual pouring in this new dynamic tilt-casting-process should be chosen in a way that the component’s surface located at its lower side prior to the start of pouring lays predominantly in the horizontal. In the case of cylinder heads, we are currently considering a starting angle of 90° as the procedural optimum, but it should not exceed 120°. As well, the end-point of pouring can be chosen freely at an angle of 0 ° +/-30 ° depending on the component’s geometry.

The docking-interface between the die and the pouring-basin is designed in such a manner that the sealing surface between the basin and the feeder-containing top-core is uniform and that an even pressure is applied. By this, the connection between the die and the pouring-basin is tight, without causing any deformations of the deck-core, which can even destroy it. After pouring, the oxide skin drops from the surface of the basin onto the top of the feeder. The sealing surface is not wetted at all and by this after undocking not metalized and therefore it does not require any cleaning between the cycles. The docking process itself takes only 3.5 seconds, which is significantly less than the filling time of a basin at this point in time would be. Since on the engineering side, very mature solutions for the entire equipment design were brought to the table, already today, the entire work flow from the scooping of the metal up to the undocking of the pouring-basin can be classified as absolutely ready for series roduction, especially because of the use of proven standard elements (see also Figure 6).

The rotation-axis for the tilt-movement was consciously chosen behind the farthest point of the casting-part on its central axis on the opposite side of the basin, whereby a falling mold filling is avoided and a predominantly controlled and rising filling of the cavity is effected. During the actual filling of the cavity, the amount of metal provided by the basin per increment of inclination has always to be greater than the demand from the cavity (see Figure 8). This results at the interface between the pouring-basin and the feeder in an increasing level of metal height when the requirement of metal by the cavity is reduced. As already mentioned before, this interface should not be influenced by any bulkheads or skimmers, but providing free flow to the metal. If this condition is not met, there will be a theoretically negative metal height at this interface and by this circumstance a turbulent and cascading metal-flow will be initiated. This precondition is one of the main design criteria for the pouring-ba in, which by this, becomes productspecific. Everything else as product-specific filling parameters is controlled by the variable and customizable rotation speed of the tilt-bench. This stable and robust parameterization results in an extremely lowturbulence shifting of the liquid metal from the pouring-basin into the mold-cavity and the entire shape contour including the interior-cavities-forming sand-cores are de facto very carefully submerged into the smoothly rising metal.

The metal flows layered against the combustion-chamber-surface-building chill-plate and remains there until the end of the actual mold-filling, without being replaced by hotter metal due to disturbing transvers currents in the metal in this area. Under these circumstances, the naturally layered temperature stratification of the cast metal is uncompromisingly maintained in which the hotter metal always remains superimposed upon the cooler metal. This in itself, represents an extremely slow-flow-process and allows rotation-speeds that are much higher in the proven practice, as estimated in advance or pre-determined by simulations. This extremely rapid filling of the cavity accommodates very low mold-temperatures and by this very short solidification-cycles (see Figure 5). Apart from the very obvious benefits of this process-design with regard to the associated benefits in terms of productivity, this approach provides to the end customer all material-related benefits that go hand in hand with a gentle, non-turb lent mold-filling and a most rapid solidification (see Figure 1-3, sheet 1, diagram 1).

The formation of an air-gap between the solidifying casting-part and the combustion-chamber-side of the die seems to be particularly very largely suppressed, thus, even when using organic binders, the formation of condensation around the water-jacket-feet turns into a subordinated problem.

The end of the mold-filling takes place in the present procedural approach, without the kinetic energy of the flowing metal would trigger any dynamic peak-pressure or shock-strike when the cavity is completely filled, avoiding even the slightest impulse. Thus, the castings remain largely free of any burrs and the surfaces formed by sand cores show a surprisingly smooth and uniform structure (see Figure 1). As well, coated diesurfaces remain extremely smooth, just like the cores, and do not even show initial signs of penetration (see Figure 2).

The extremely good surface quality is also owed to our decision to pour only in the second position of the carousel, which is why only after another 56 seconds the carousel indexes to the next position, when already a robust boundary shell of solidified metal has been formed, even in the shapes built by core-surfaces. The very rapid mold-filling enables extremely low mold-temperatures, especially in the combustion-chamberareas, where DAS of less than 18 microns are measured in the walls between the combustion-chamber and water-jacket (in a depth of 1 mm) with extremely high consistency (see Figure 3).

Operational Aspects

Already during the introduction, we went into the interdependencies between process stability and productivity. We regard stable processes as the essential precondition for productivity on global benchmark level. But in return it is very obvious from our perspective that stable processes also require robust and reliable manufacturing equipment (machinery, tools and fixtures) in order to actually take ultimately use to the full extent of the underlying opportunities and potentials of an outstanding process capability. With frequent interruptions because of any recurrence of equipment- or tooling-interferences, one permanently destabilizes even the most robust processes.

In our view, the manufacturing-concepts used in gravity-die-casting can be classified as follows: the least complex system is the single- or one-station casting-bench, but in reverse this set-up also bears the slightest potential for improving efficiency. With regard to the multi-bench-concepts, on the one hand we can find the so-called shuttle-systems, i.e. the casting-benches carrying the dies move linearly to the operator-position, the pouring-point and further peripheral equipment; on the other hand, we can find in this group the socalled in-line linear-systems in which the pouring-robot and operating-devices have to move to the fixedstationed casting-benches carrying the dies (see Figure 9). And because the imagination of engineers becomes hardly limited at any time, there also exist mixed systems, in which both, the casting-benches with the dies, as well as the pouring-robots and operating-devices are in constant motion. According to our true belief that for any optimal use of manufacturing-equipment, he operating personnel should in principle fully understand the interactions of the general arrangement, we see in the latter combination, the fewer opportunities to reach an exemplary overall equipment efficiency.

Regarding the number of stations, we find nowadays systems in use, consisting of 2 to 12 casting-benches which in some cases, can also be occupied with double-impression tools. As we try to demonstrate in the following exposition however, it is purely mathematical that the number of stations which represent the optimum of efficiency is achieved when we manage to work with an equivalent between the operating-time and the process-time.

In our opinion, the Tridem®, a shuttle-system which operates 3 dies, has represented the optimum in efficiency in cylinder-head-manufacturing-technology for many years. The Tridem® emerged through an evolutionary development process, taking place in the early 90s, from the tandem®, a shuttle-system operating 2 dies, when the casting process itself and the available equipment- and tooling-technology could be further improved in a way that the individual reliability of tools and equipment could be stabilized to an extent that the overall out-put per die in this arrangement could be increased at all. When the complexity of the cylinder-heads had begun to rise further, four-slide-molds became predominant and by this the Tridem® was squeezed-out of the market and mostly replaced by in-line linear-systems.

It is important to note that in the case of shuttle-systems, the availability of the overall system results from the product of the individual availabilities (1) of each casting-station. The in-line linear-system is with this respect superior, because in this arrangement, the overall availability results from the average of the individual availabilities (2), since each station can be individually shut down, independently from the others. This option is not as simple to be implemented in the shuttle-systems. Alone from this perspective, there is a certain advantage with the in-line linear-systems, which is often abused to have to deal less consistently with the stability and robustness of processes. Perhaps their dominance might be owed to this concession.

If we compare in-line linear-systems and shuttle-systems with three stations, the following formula may contribute to a better understanding of the situation:

OEE1.1 x OEE1.2 x OEE1.3 > OEE2.1 + OEE2.2 + OEE2.3

3

If you decide to focus on the process stability, in order to advance it further in a way so that the result for the overall equipment efficiency of a new shuttle-system (1) is increased and by this larger than that of an existing in-line linear-system (2), then you can enjoy more serious benefits in the field of additional efficiencygains, related to the fact that in a shuttle-system, the casting-benches move to the work-stations and not vice versa, as it is the case in the in-line linear-systems, where the operators as well as the pouring- and operating-units must move to the casting-benches. Only through this decisive step, we are trying to demonstrate by this publication as well, we will be rewarded with further crucial improvements with regard to the efficiency of the operating- and logistic-staff, as well as the peripheral devices and by this, also of the capital employed.

While watching an operating in-line linear-system, only the long-range movements of the pouring-robot, the part-extraction-robot and the core-setting-robot will instantly convince the observer by how much dispensable effort we have bought this relieve from an exemplary process-control. If we further incorporate into our considerations the distances which must be covered by the workers and take into account the more complex logistics for the metal- and core-supply, as well as for the removal of the castings, then, only by this analytical approach, we will not any longer be absolutely convinced that we will achieve the most effective solution with the currently dominating in-line linear-system as the generally underlying concept. However, the decision for the alternative shuttle-system requires our uncompromised readiness for extremely consistent work on the quality of the tools and the operating equipment, what with its sophisticated and reliable design only defines a starting-point of this journey (see as an example Figure 10).

The til now unmentioned concept of the carousel represents basically nothing but a circularly arranged shuttle-system. In the case of a carousel, the question regarding the optimal number of stations which are being provided, becomes more important for our further considerations. In this context, we would like once more to address the formula, which we have already used before, to compare a 6-station-carousel (3) with a 3-station shuttle-system (1):

OEE1.1 x OEE1.2 x OEE1.3 > OEE3.1 x OEE3.2 x OEE3.3 x OEE3.4 x OEE3.5 x OEE3.6

If one accepts what had already been manifested by the Tridem® for decades, that 3 stations are sufficient for mutually balancing operator- and robot-intervention-times on the one hand and process-time on the other hand, then it must be assumed that more than three stations in a shuttle-like arrangement will lead to lower net-out-put per die, since each additional station will decrease the total OEE, because the OEE of the 4th, 5th and 6th Station will be in any case less than 1. The same law is to be applied, in our opinion, if multiple-impression-tools are utilized, even if we will not take into account that in addition there usually are mutual negative effects implied between the cavities within multiple-impression-tools or double-benches.

This background explains as well why we have eventually decided for the 3-station-carousel as the most promising solution. If we then additionally put into consideration the considerably faster cycles in the decoring- and sawing-cell (also owed to the fact that there is no need any longer to cut-off a gating system), the merger of two 3-station carousels to a TwinCarousel-Line is comprehensible. In our opinion, this approach provides in particular the jobbing-foundries with the process-capability, the productivity and the flexibility they need in their cooperation with the OEMs on the one hand, to be able to offer competitive pricing at full costs and on the other hand to ensure the most stable utilization of their installed capacities, despite the OEM’s volatile volumes (see Figure 11). And without question, third, an outstanding and reliable quality represents anyhow the pre-condition for any new order. When using our newly developed dynamic-tiltcasting-process in this lay-out-arrangement there are even mo e remarkable up-side-potentials with regard to these, the jobbing-foundries permanently assigned requirements (see Figure 12).

Technical and Econmical Relevance

Looking at the technical and economical relevance of the present approach more closely, in particular the outstanding process-capability and -robustness needs to be emphasized. With several hundred components that were already produced in pre-serial-production the cavity-filling- and solidification-induced defects in total were measured well below 10,000 ppm. In the X-ray-examination (100 %) as well as in the leak-test (100 %), the parts were tested totally without any detected defects. During casting, the overall system reacted relatively robust to wear and tear of the die-coating, without any air-inclusions, cold-runs or other superficial imperfections becoming visible as a problem. The process responded calmly to the wide range of casting-temperatures we have chosen to be evaluated, which had been between 680 °C and 780 °C in the bail-out-furnace; only the solidification-time had to be adjusted accordingly. The components most critical dimensions (combustion-chamber-depths and intake- and outlet-port-posi ions) were very stable with regard to CpK-levels within their most demanding tolerance-windows. The DAS (Dendrite Arm Spacing) could be maintained without specific efforts, but dependent on pouring-temperature, below less than 18 microns in the wall (fire-deck) between the combustion chamber and water jacket (in 1 mm depth). With special measures with regard to the die-coating as well as to the die-temperature-control in the combustionchamber-area, even lower values can absolute consistently be achieved, dependent on the alloy. This, however, would have to be confirmed experimentally in each individual case for a respective product.

Based on the material-related investigations carried-out so far, it was clearly demonstrated that modern, high-performance cylinder-heads for petrol- and diesel-engines can be absolutely reliably produced with this new dynamic tilt-casting-process. The reproducibility and robustness of this process exceeds anything the authors have personally experienced so far with any other application. Thus, this new process will also meet the objective that a global roll-out of the production of these components should be feasible with manageable risks, even if the skill-level of the receiving manufacturing-location would be classified as still developable. The present technology is only influenced to an extremely limited extent by the ‘workers', but defines itself almost exclusively via the system-cybernetics, the tool-technology and the geometry of the pouring system. All other parameters are dependent on the reliability and capability of the tooling, the operating equipment or other plant-specific hardware.

The performance potential of a TwinCarousel system using our new dynamic tilt-casting-process (see sheet 2) is so convincing that it could be worthwhile for aluminum-jobbing-foundries in any case, to think seriously about the (re-)entry into this product portfolio, especially in the light of the currently ailing supplier oligopoly in this market segment. During the acceptance tests of the equipment, the measured out-put lies about 25% above the globally known benchmark and is therefore apparently likely to outperform the industry average even more significantly. The balanced allocation of operational and process-steps to the three positions of the carousel is apparent from the graph (see Figure 13, sheet 2). Assuming that a TwinCarousel can be operated by only 3 workers (see Figure 14), it becomes quite obvious that with this new technology the achievable economical results are more dependent on the attainable overall equipment efficiency than of the country-specific direct labor-costs.

Future Perspective

We do not want to conclude, without having outlined our personal vision for this technology in brief:

The first glance at the specific plant-layout of this arrangement clearly demonstrates that the cooling tunnel now dominates spatially and energetically the overall concept. In this regard, however, first trials were already very promising to replace this piece of equipment by a cold fluidized bed. With an already verified cooling time of approximately 300 seconds to nearly room temperature, only 5 positions in such a fluidized bed are required to quench the output of one carousel to almost room temperature. The throughput of air in this process can expectedly being reduced by the factor 5 compared to the currently used solutions. Also significantly less production area for a TwinCarousel-Line would then be required.

The rapid cooling of the casting-part including all the remaining sand cores in a cold fluidized bed of regenerated quartz sand avoids the usual recalescence in the rapidly solidified areas of the casting-part and as a consequence, in the majority of cases the solution annealing during a heat treatment can become unnecessary. As the logical continuation of this approach one can also try to maintain the then equalized residual heat in the casting-part and its riser for the artificial aging of the component. By this, the entire system would become in size significantly smaller and as a process much more energy efficient. Then, that objective would quite closely aligned at the ongoing changes in the social and political values of our modern civilization.

The fact, that during its entire ride around the casting-axis, while the cavity is being filled, the pouring-basin is actually undocked from the robot, was basically intended as an essential prerequisite, to take this innovation into a further stage of development with this very same procedure. The entire casting-bench can then be moved into an autoclave, and by this the entire pouring- and solidification-process-step can be carried-out under elevated ambient pressure. In essence, the pouring and solidification under increased ambient pressure is well known from the counter-pressure-process, which had been developed in Bulgaria decades ago (see Herbert Smetan: "The counter-pressure-casting-process for light metal casting alloys – process-specific opportunities in industrial application"; GIESSEREI 19/82). However, the counter-pressurecasting-process is based on the principles of the low-pressure-casting-process so that the relatively high costs of equipment in relation to the rather poor productivity appear njustified. In my view, this is the main reason why until now, this process could not become more dominant in the foundry-industry.

On the other hand, however, it could have been proven that particularly the high-strength and hightemperature-resistant silicon-free aluminum-foundry-alloys can be quite satisfactorily processed with this procedural approach. These very special foundry-alloys are well-known, but when processed by conventional methods, their castability is classified as difficult to poor. This assessment is strongly attributed to the fact that these alloys are extremely prone to inter-crystalline micro-shrinkage and associated therewith to hotcracks. This most delicate and dispersed micro-shrinkage along the grain boundaries influence most disadvantageously the mechanical properties of aluminum alloys, quite similar to the graphite-flakes in grey cast iron. However, during the entire solidification, the high ambient pressure promotes the infiltration of the residual melt into the crystallizing sponge. Since the ambient pressure is applied on all sides, the infiltration (penetration) of melt into the sand-cores and the coating on the die-surfaces is inhibited.

It will be shown in the years to come, whether a combination of this new dynamic-tilt-casting-process in conjunction with an autoclave, can open a wider window for the industrial application for these highly sensitive alloys, despite their rather restricted castability. In particular, we want to refer to future generations of cylinder-heads, especially if the specific power-density of internal-combustion-engines should still continue to rise further.

And finally we would like to close with a reference to car-body- and chassis-components. The extreme high pouring-speeds that were even possible with cylinder-heads, indicate a certain capability of this innovative dynamic die-casting-methodology to produce large-area and thin-walled components in high-purity primaryalloys very economically and reliably. Then, these components are likely to contain sand cores as well, in order to use the stress-neutral fiber for interior cavities and by this, realizing further weight-savings. But this opportunity must experimentally be demonstrated in further trials, as well as the use of high-strength, lowsilicon aluminum-magnesium-alloys for these applications.

Partner

Foundry Corporate News

Topic Pouring, Gating, Feeding

Topic Gravity diecasting

Topic Low-pressure diecasting

Fill GES.M.B.H. - New Dynamic Tilt Casting

Reading time: min

[47]