Fill revealed the way to the future of metal machining and processing at the "Euroguss" trade fair in Nuremberg.

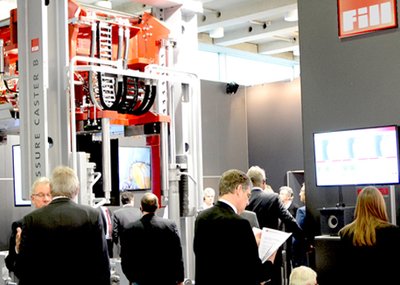

Individual complete solutions of the highest precision with a focus on the field of lightweight engineering: Fill Machine Engineering presented itself as an ideas factory and innovator at the 10th anniversary edition of the "Euroguss" trade fair from 14 to 16 January 2014 in Nuremberg. From the raw material to the finished and tested component. At Fill, everything comes from a single source. The Fill Cocktail Lounge integrated into the exhibition stand became a popular meeting place for the international foundry industry.

"Many interesting meetings and discussions with trade visitors, numerous contacts and new international customers. Euroguss 2014 was a complete success for us," summarizes a satisfied Thomas Rathner, Head of the Metal Competence Center at Fill. Among other products, the Upper Austrian machine engineering experts presented pioneering technologies in the field of metal machining and processing in the form of the innovative syncromill range of machining centers. Further highlights on the Fill exhibition stand included extremely productive, low-pressure casting machines and the trimmaster press deburring press.

Light, lighter, Fill

Lightweight construction is a major trend in the industry. Here in particular, Fill can score highly with advanced lightweight production technology. Longstanding expertise in the foundry sector, combined with innovative ability and a wealth of ideas, make all the difference. The syncromill c machining center facilitates synchronous component processing from two sides simultaneously. Aluminum, steel, and other materials are machined with the highest precision. Extremely economical and efficient processing is possible thanks to use of intelligent clamping concepts. In its role as general contractor, Fill assumes responsibility for the customer's production engineering - from the rough casting to the machined, cleaned, tested, and assembled finished part.

Efficient deburring in volume production

The Fill trimmaster press deburring press facilitates cost-effective punch-deburring of castings in large batches. Extremely short cycle times and individual adaptation of tools and punch pressure to the respective casting properties ensure maximum flexibility. Extremely high traversing speeds are achieved thanks to the suction hydraulics. Open access to the clamping surface from two sides is particularly well-suited to automatic loading and removal.

Turbulence-free casting

The innovative Fill low-pressure casting machines for the production of high-quality aluminum castings pile on the pressure, while paying particular attention to quality and cleanliness. The low pressure caster is noted for casting free from turbulence with high productivity and the production of several components in a single casting operation. In the form of the gimatec 800/1000 – a further refinement of the standard GIMA machine – Fill has expanded its product range in the field of low-pressure casting. Significant for the gimatec 800/1000 is the new Siemens S7 controller with optimized casting control for simple operation and transparent data output.

Partner

Foundry Corporate News

Topic Pressure Die Casting

Fill: Production systems "cast in the same mold"

Reading time: min

[6]