The “Full Mold Casting” process, which was introduced in 1964, brought a big revolution to Kimura Foundry and the company has grown to be recognized as “KIMURA of Full Mold Casting” by the industrial production world.

By specializing in the Full Mold Castings Process for over 50 years, Kimura has become capable as a supplier into a lot of new fields. Simultaneously, it has also developed manufacturing technologies based on Information Technology (IT), such as modeling by CAD/CAM, various measurement systems and casting simulation through production mainly of Full Mold Casting. As a result, Kimura succeeded in establishing a new casting technology integrating the Full Mold Casting and IT. The company continues to move forward, applying its technologies to utilizations of 3D printers, reverse engineering and so on.

Kimura Group has just opened a new foundry, Kimura Foundry America, in Shelbyville, IN, USA

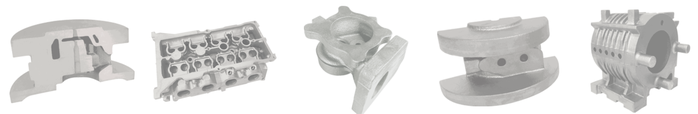

to contribute especially to its R&D market. It specializes in providing high quality Rapid Prototype (RP) castings and small lot production services. RP castings are produced with zero defects in just 5 days.

With proven expertise in precision design, highly advanced pouring, finishing, inspection, machining and rapid prototyping, Kimura has longstanding relationships with customers across industries, including automotive and Tier 1 suppliers, large and small engine manufacturing, machine tools, industrial pumps, oil, gas & renewable energy, construction and mining and agricultural equipment.

Focusing on a technology leads to a new technology, and new technology makes a new world.

Kimura's technologies have infinite potential, which will be developed and expanded to various fields. By being a world-leading foundry, Kimura's technological innovation will support its customers in a way that contributes to all the people in the world.