The technology group Rheinmetall AG has won a follow-up order from a well-known German carmaker to produce aluminum engine blocks with a total value of over €100 million.

Full-scale production is planned to begin in 2023. The lifetime of the contract extends beyond 2030.

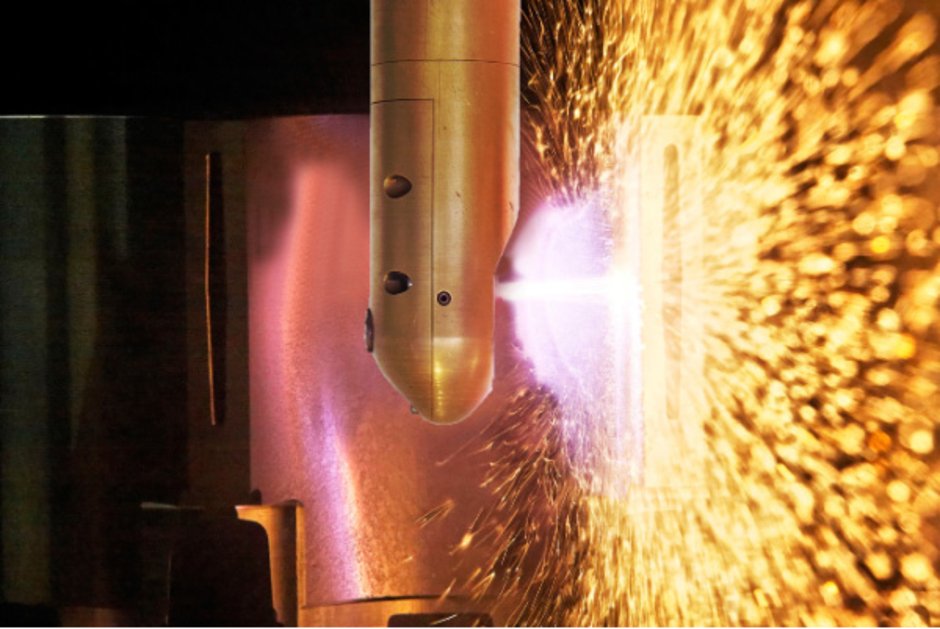

The company has been supplying the premium automaker with engine blocks for various vehicle models ever since the 1990s. The current model is produced using low-pressure die casting, while the newly ordered engine blocks will be cast using low-pressure sand casting.

Developed by Rheinmetall subsidiary KS HUAYU AluTech GmbH, this innovative casting method enables the production of highly integrated cast parts that combine maximum geometric freedom with optimum weight. Furthermore, the casting method responds to steadily rising expectations of auto manufacturers with regard to materials characteristics and component strength.

Looking ahead, sustainability is set to become an increasingly important aspiration in the automotive industry. Therefore, another criterion in awarding the contract was a holistic consideration of the carbon footprint, coupled with the security of having the shortest possible supply chain.

Thanks to its production plant in Neckarsulm, Rheinmetall was able to meet this proviso.