It weighs in at 8,000 tonnes and grows over 70 metres high in its steel shell: thyssenkrupp Steel Europe AG is setting new standards with its new hot-dip galvanising line in Dortmund. In the future, one million tonnes of steel strips will be hot-dip galvanised here per year together with the existing plant at the Westfalenhütte. The easy-to-process and durable sheets are in demand above all from car manufacturers and producers of household appliances. In October, the new plant was opened in the presence of Minister President Hendrik Wüst. The construction project was accompanied by specialists for large-scale projects in industrial and plant construction from Drees & Sommer SE, a consulting firm specialising in construction and real estate.

Steel for vehicles and household appliances

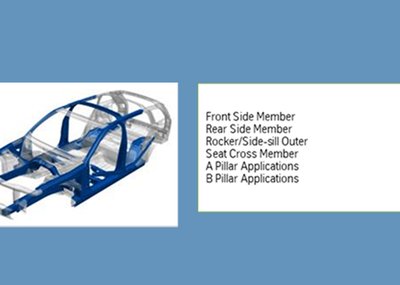

The new FBA 10 hot-dip coating line from thyssenkrupp Steel in Dortmund will in future produce mainly steels for vehicles and household appliances on an area of around 12,600 square metres. © thyssenkrupp Steel Europe AG

For Dr. Heike Denecke-Arnold, COO of thyssenkrupp Steel, the new line is a promising investment in the site and an important signal to the workforce: "With the new hot-dip coating line, our Dortmund site is developing into Europe's largest centre of excellence for hot-dip galvanised strip. This will enable us to meet the requirements of our customers from the automotive and household appliance industries. With this investment, we are not only securing the existing 1,300 jobs at the site, but also creating around 100 new jobs for highly qualified employees." Hot-dip galvanised steel provides vehicles with long-lasting protection against corrosion. This makes the steel particularly sustainable, as it can be one hundred percent recycled without any loss of quality.

Multitasking in the construction process

Right from the start, the planning and construction of the demanding, up to 75-metre-high steel structure posed special challenges: After several World War II bombs were found and had to be recovered during the site development and civil engineering work, there was the threat of an enormous delay in construction. Klaus Martin, Drees & Sommer project team leader in charge of assembly construction management, therefore used Lean Construction Management to identify collisions between individual trades and minimise delays: "In contrast to traditional construction management, in which a planner only brings together the individual trades planned by various project participants at the end, Lean Construction Management relies on cooperation from the very beginning. Many construction and assembly works - from the foundations to the steel structure hall to the plant itself - had to run in parallel and be coordinated accordingly," Martin explains.

Traditionally, the classic construction trades and plant construction operate in separate teams. Thanks to Drees & Sommer's integrated project management approach and the use of Drees & Sommer experts in both construction and installation management, the representatives of the individual trades were able to grow together to form an integral team - for optimum processes and a smooth construction and installation process. "We had a detailed schedule that was coordinated between the assembly and construction management teams and timed to the week. This meant that we knew at all times how many employees were on the construction site and which materials and machines were needed at what time," says Martin. The construction experts can accelerate the construction progress with this method compared to the conventional approach.

Construction site logistics on a large scale

In the course of delivery and goods logistics alone, several hundred subcontractors had to be organised. The individual components for the hot-dip coating plant were manufactured in different countries, which resulted in complex delivery logistics. In addition to the challenge of setting up a global supply chain for sequence-accurate delivery to the construction site in Dortmund, the restrictions of the worldwide Corona measures made on-time delivery difficult. Because the plant was delivered in large parts well in advance of the erection to ensure deadlines, a huge storage area and corresponding warehouse management was also required, which was set up and maintained on the neighbouring property. Deliveries had to be timed to prevent waiting times, and a road infrastructure with special access points had to be created that heavy goods vehicles could also use. Last but not least, the appropriate staff had to be provided and organised. On some days, up to 20 lorries delivered goods that had to be sorted, stored and labelled to ensure smooth assembly later on. At times, 15 to 20 employees were working in two shifts just receiving and storing the goods. "We managed all this by actively planning the construction and assembly sequence within the project. This also enabled us to compensate for delays in the further construction and assembly progress," Martin sums up.