HÜTTENES-ALBERTUS is a leading international manufacturer of chemical products for use in all established coremaking and mouldmaking processes in foundries. In cooperation with ASCO CARBON DIOXIDE LTD, a full service provider in the wide range of CO2 and dry ice blasting technology, new knowledge regarding the removal of coatings of moulds while using dry ice and combination blasting should be obtained. The aim is to pass forward a complete application package containing the gained know-how to the customer.

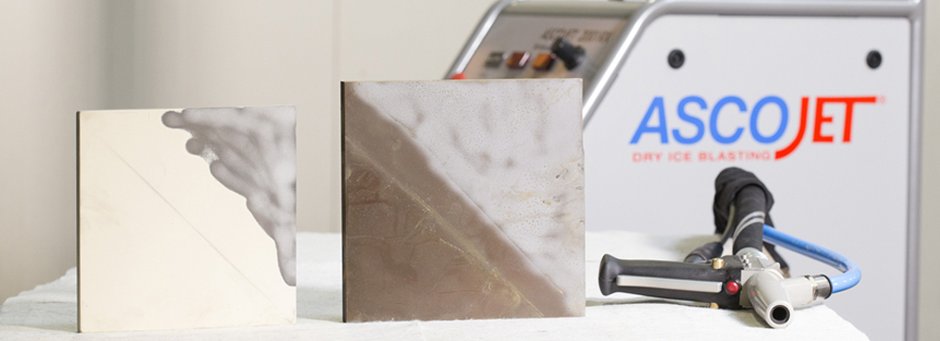

Mould and tool cleaning has great importance in foundry operations. Especially true when it comes to optimal cleaning results of moulds and core boxes since an efficient cleaning process does not only increase quality but also boost productivity while optimising costs. ASCO CARBON DIOXIDE LTD is specialised in introducing the ASCOJET dry ice blasting system to foundries and optimising it by offering customised solutions. Also, HÜTTENES-ALBERTUS develops its products in close collaboration with foundries to ensure user-friendly applications.

In open dialogues with foundries, both companies figured out that there is still no efficient overall solution for partial or complete removal of coating of moulds. Presently, heavy metal casting foundries need to remove the mould´s finishing coating several times a day. In addition, a regular removal of the base coating and an occasional roughening of moulds is required. The last one is an important criterion for the adhesion of the coating. The removal of the finishing coating is mostly unproblematic and can be done efficiently with pure dry ice blasting which is a common practice in the foundry industry. However, when it comes to the removal of the base coating or the roughening process, pure dry ice blasting is of limited suitability, as the procedure takes too long or the desired effect cannot be reached due to physical reasons. Pure abrasive blasting with sand or glass beads is too aggressive and would damage the surface of the moulds. In addition, pure abrasive blasting causes high secondary pollution or clean up requirements.

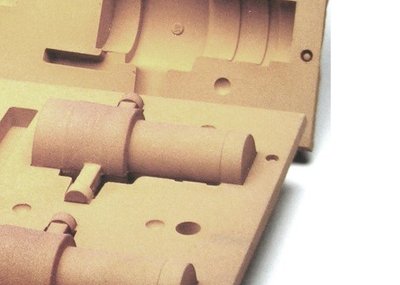

Reason enough for both companies to pool the joint expertise to offer an optimal overall solution to the end user. The cooperation goes as follows: HÜTTENES-ALBERTUS is working on a special coating composition for smoothing porous moulding surfaces. For this purpose, finely to highly grounded base material is used. The coating isolates the mould´s ground and protects against thermal stress.

The common aim is to provide foundries not only with a high quality coating but also with the perfect complementary cleaning method. This is where ASCO steps in because the recently launched ASCOJET Combi blaster 1708 can close this application gap in the cleaning process.

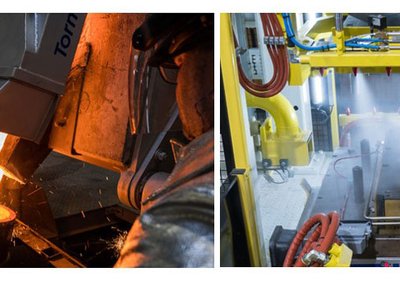

The new ASCOJET blasting unit is the perfect combination of gentle cleaning with dry ice pellets and the additional, abrasive effect of a specially selected additive. Udo Hinze, Area Sales Manager Dry Ice Technology for Northern and Eastern Germany at ASCO, explains the advantages of the ASCOJET Combi blaster 1708, "Depending on the process requirements, the abrasive material can be added to the dry ice stream. The cooling effect of the dry ice offers an optimal material protection even while blasting with dry ice and additive. As persistent contaminations like the basic coating can be removed effectively thanks to the added abrasive material. In addition, moulds can be roughened optimally so that the newly applied coating adheres perfectly." Further, Hinze points out the low need of blasting material which results in almost no secondary pollution. The higher cleaning performance of the blasting unit also allows to work with less compressed air resulting in a considerable reduction of noise emission.

Another unbeatable advantage of all ASCOJET blasting units: The application can be used directly on the moulds without disassembling them which is why the production can be continued immediately after the cleaning process and the method can be integrated into the working process easily. This eliminates costly production downtimes and quality losses and increases process safety with little effort.

Marco Pellegrino, Managing Director of ASCO, is aware of the specific characteristics of such a profitable collaboration, "HÜTTENES-ALBERTUS as well as ASCO bring in a lot of knowledge and expertise in the wide field of dry ice blasting in foundries. We coordinate our products and application processes in regularly scheduled test runs. For us as a supplier it is of utmost importance to be in direct contact with the customer and not to develop past the market. The launch of the ASCOJET Combi blaster 1708 proves once again that ASCO acts solution-oriented and in accordance with needs of the end user which are foundries in this particular case. The same applies to HÜTTENES-ALBERTUS who sets new standards in terms of efficiency in mould cleaning thanks to the development of an optimised coating for our ASCOJET dry ice blasting system.

Heinz-Gilbert Klussmann is Product Manager Release Agents at HÜTTENES-ALBERTUS and explains why the cooperation with ASCO is already a success, “We closely cooperate with the foundries and consistently adjust our products to ensure their technical and practical suitability. Not only does this process involve further development of established products, but it also takes us in completely new directions. For precisely this new ways we require a reliable partner which we found in ASCO. As a complete provider around CO2 and dry ice, ASCO´s knowledge is embedded in a total CO2 background and together we directly and easily focus on the very best solution. This very best solution is then to be passed on to our customers."

Common test runs are now used to define the optimal parameters regarding blasting pressure and necessary amount of dry ice and/or abrasive material for most efficient removal of the newly developed coating structure with the ASCOJET Combi blaster 1708. Also, the possibility of “repairing” coatings by means of cleaning with fine dry ice particles is tested. This is about partial removal of solving structures without stripping of the whole coating. Thus, a complete package consisting of application engineering and optimised coating can be offered to foundries in the future.

Partner

Foundry Corporate News

Topic Chemicals

Topic Discharging, Decoring, Fettling, Finishing

Topic Sand & Binders

Topic Hand-mould casting

Topic Machine mould casting

HÜTTENES-ALBERTUS and ASCO set new standards for mould cleaning in foundries

Reading time: min

[6]