In a bid to improve the cost competitiveness of pure electric vehicles, Toyota has announced plans to adopt integrated die-casting technology. According to sources quoted by the Financial Associated Press, this technology will be implemented in Toyota’s pure electric vehicles set to hit the market in 2026, with the aim of boosting sales by enhancing cost competitiveness. Additionally, Toyota is also considering applying the technology to models beyond pure electric vehicles.

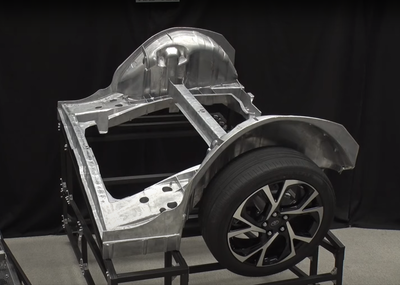

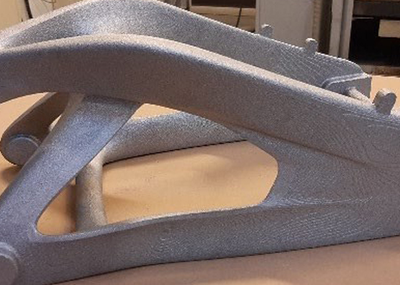

Integrated die-casting refers to the manufacturing of large-scale aluminum parts using large-tonnage die-casting machines. This technique involves the integrated processing of automobile body structural parts, eliminating the need for welding and assembly processes. The use of integrated die-casting is expected to reduce weight and costs substantially, making it a preferred choice for automakers.

CITIC Securities has analyzed the advantages of the integrated die-casting process, highlighting its significant weight reduction and cost reduction benefits. Following the successful integration of die-casting technology in front and rear floor assemblies, it is predicted to further expand its application across other parts of the vehicle’s body-in-white. As a result, die-casting machines are expected to become the central equipment for vehicle manufacturing.

Kato Takero, the president of Toyota’s pure electric vehicle division, known as “BEV Factory,” stated that implementing integrated die-casting technology will not only streamline the production process but also maximize land utilization in the factory.

Toyota aims to sell 24,000 pure electric vehicles in 2022 and has recently launched an ambitious electrification strategy. The new strategy, announced by Toyota Motor’s new president, Tsuneji Sato, outlines plans to introduce 10 new electric vehicles through the Toyota and Lexus brands from 2023 to 2026. To achieve global annual production and sales of 1.5 million electric vehicles by 2026 and an annual sales target of 3.5 million by 2030, Toyota will establish a dedicated department focused on researching, developing, and manufacturing electric vehicles.

Furthermore, Kato Takero has previously indicated that the future of manufacturing will be “BEV half.” This concept involves a modular structure and a vehicle automation mobile production line technology that reduces both the production process and factory investment by half, while also reducing production preparation lead time.

Bank of China Securities has released a research report emphasizing the growing significance of integrated die-casting technology. As car companies increasingly adopt this technology to meet demands for lightweight, efficient, and cost-effective vehicles, the application sites for integrated die-casting are expanding rapidly. It is predicted that the market size for integrated die-casting will reach 22 billion by 2025, with a compound annual growth rate (CAGR) of 133% over four years.

In summary, Toyota’s adoption of integrated die-casting technology in its electric vehicles is expected to enhance their cost competitiveness and contribute to the company’s electrification efforts. With plans to launch 10 new electric vehicles by 2026, Toyota is positioning itself to become a key player in the global electric vehicle market.

Source: www.Caijing.com Author: Jia Zijian