To give an answer and a solution to these problems, Motultech Baraldi has developed a line of high performance products by introducing the PISTOCAST line based on synthetic oils with very high additives. One of the most successful products of this type was PISTOCAST 16 which made it possible to obtain very high quality castings, it is a "clean" product, free from graphite, easy to dose and with the possibility of having different viscosities and therefore adaptable to customer needs.

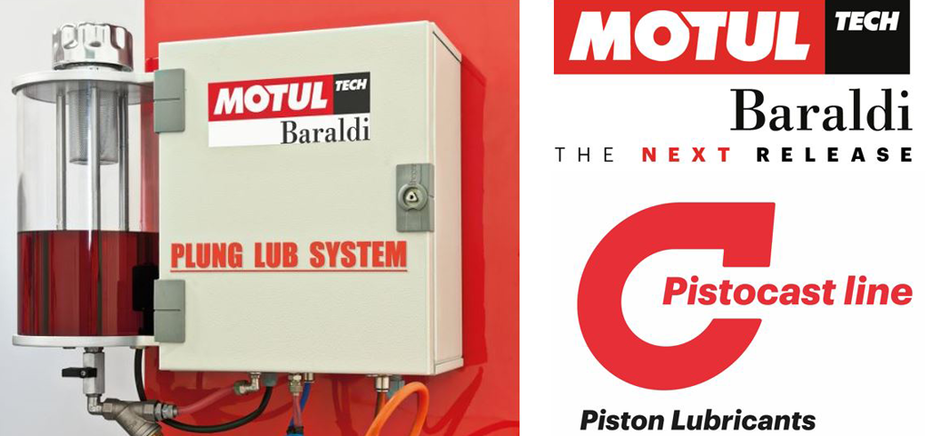

Linked to the effectiveness of the PISTOCAST product is the method of its application on the plunger, and for this reason we have developed our PLUNG LUB SYSTEM application system which allows a very accurate volumetric dosage (i.e. with the guarantee of constancy of the applied volume regardless of the room temperatures). In more recent years, also thanks to the evolution of structural castings towards "giga" dimensions and to equally "giga" tonnage presses, the quality problems of the castings have also increased and with them those linked once again to the shot sleeve-plunger system. This means much larger diameter plungers and longer and wider shot sleeves, often made with materials with different thermal expansion coefficients and with different types of rings, where friction can reach very high levels. Here once again our experience and laboratory tests have led us to new formulations and to a high performance product such as PISTOCAST 48.

With this product our customers have obtained:

- Improved performance compared to products containing graphite with a reduction of friction between plunger and shot sleeve in the 1st injection phase of around 15%;

- Increased life of the shot sleeve-plunger system up to 20%;

- Better cost/performance ratio compared to products in pellets, reinforced mineral-based oils, and water-based products.

They were also able to eliminate:

- The flames during the pouring of the alloy into the shot sleeve;

- Acrid fumes in the environment;

- The sticking of the container on the shoulder of the press.

In the PISTOCAST product line it is also possible to find versions with synthetic oils of vegetable origin and therefore respectful of the environment and operators.

When planning the production of structural castings it is advisable to immediately tackle the problem of plunger lubrication and for this reason the Motultech Baraldi technicians will be able to put their technical consultancy and our best products at your disposal.

For more information on PISTOCAST and PLUNG LUB SYSTEM products: