They employ two key technologies: Binder Jetting Technology (BJT): Kennametal utilizes BJT for crafting wear-resistant components as well as Laser Powder Bed Fusion (LPBF): LPBF is employed to manufacture the body of their tool holders using iron-based materials.

In 2019, Kennametal introduced custom, fully dense cemented tungsten carbide solutions to the market. These cutting-edge solutions are designed, optimized, and manufactured within a dedicated, full-scale production unit. Kennametal’s first hardmetal carbide 3D printed solutions were in the robust WC-17% Co grade (KAC89-AM-K). Subsequently, in 2021, they launched an even more resilient tungsten carbide grade with a 13.5% CoNiCr metal binder (KAR 85-AM-K), specifically tailored for their additive manufacturing process.

These innovative solutions find applications across diverse industries, including Oil and Gas, Mining, and Automotive. Kennametal’s commitment to excellence continues to drive advancements in additive manufacturing.

Adoption of Additive Increases with Customers and Markets

As the adoption of additive manufacturing gains traction, customers and markets are increasingly receptive to incorporating it into their procurement strategies. The establishment of new standards and the successful production of field-tested parts contribute to the growing acceptance of this technology.

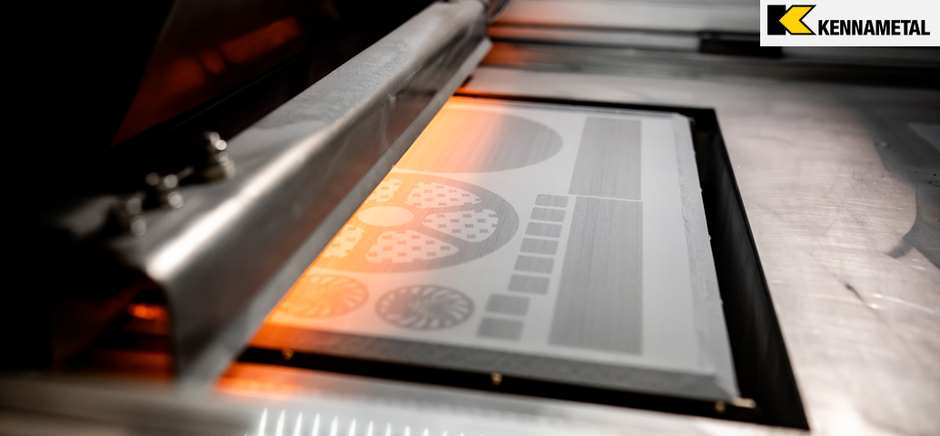

When using binder jet technology, the process is akin to traditional carbide manufacturing, resulting in a “green part.” this green part requires subsequent sintering to achieve full densification. Kennametal’s additive grades have been meticulously designed to match the properties of their conventional counterparts. Consequently, customers can expect consistent field performance, regardless of the chosen manufacturing method.

To validate materials and manufacturing processes, conventional parts are often tested alongside their additive counterparts. Alternatively, customers promptly embrace Design for Additive Manufacturing (DfAM) to avoid the sometime-consuming delays associated with tooling. While not every part is suitable for additive manufacturing due to design complexity or manufacturability constraints (such as traditional parts currently made via investment casting), there is still value in reducing inventory, lead times, and potential cost savings.

Value Proposition: Increased performance due to

- DfAM,

- shorter lead time,

- JIT inventory,

- material upgrade,

- potential cost savings over traditional/conventional manufacturing with tooling, shaping, etc.

- Tungsten Carbide outperforms in harsh environments, metal on metal, erosive

Tungsten Carbide for Harsh Environments

In demanding environments prone to erosion, cemented tungsten carbide is a commonly employed material. Unlike softer materials such as iron-based alloys, cobalt-based alloys, and nickel-based alloys, tungsten carbide withstands wear and minimizes costly downtime and repairs. However, printing tungsten carbide using a laser-based system presents challenges due to uneven heat transfer and the intricate multiphase composition of cemented tungsten carbide. Possible defects include undesired phases (intermetallic brittle phases like W2C), cracks, pores, and inhomogeneous microstructure. With over 80 years of expertise in tungsten carbide solutions, Kennametal offers a comprehensive range of solutions across their organization, including powders, cladding, and press-shaped products.

Outlook

The adoption of additive standards, particularly within the Oil & Gas and Automotive sectors, has catalyzed interest in testing this technology across various markets and applications. Kennametal Additive’s future endeavors will center on introducing their next tungsten carbide grade: a WC-10% Co grade. This new grade promises enhanced wear resistance compared to their existing two grades, while simultaneously expanding the technology’s applicability to diverse markets, products, and applications. Additionally, Kennametal’s materials and manufacturing expertise extends to potential solutions for the brake disc market, with more exciting developments on the horizon.