Through targeted investments in new technologies, digitalization, and the development of strategic capabilities, the company is strengthening its position in key industries and accelerating its market- and customer-oriented approach. This is particularly evident in the dynamically evolving aerospace sector: in 2024, MAPAL established the Global Organisation for Assembly (GOA), consolidating its expertise in aircraft final assembly – a crucial step in serving globally operating customers more quickly and efficiently. The integration of subsidiary c-Com and the acquisition of the Italian company X-Pro S.r.l. – a specialist in turnkey projects and clamping solutions – further underline MAPAL’s ambition to actively shape technological development and fully meet customer requirements.

These forward-looking activities are taking place against the backdrop of a challenging economic environment. In the 2024 fiscal year, the MAPAL Group recorded a 6.3 percent decline in sales to €551 million. This was mainly due to weak overall economic conditions and ongoing uncertainties in key sales markets. The outlook for fiscal year 2025 remains cautious in light of this situation.

“After a disappointing first half of the year, we currently expect a further decline in revenue of up to five percent,” explains Dr. Jochen Kress, Managing Director of the MAPAL Group.

In response to these developments, the company has adjusted its workforce structure to reflect changing market conditions. Vacant positions were not refilled, and the MAPAL Group closed 2024 with a total of 4,850 employees. In 2025, targeted capacity adjustments are also being made at the sites in Aalen, Altenstadt, and Pforzheim. Thanks to socially responsible solutions, compulsory redundancies were largely avoided. “As a family-owned company, we feel a special responsibility toward our workforce,” emphasizes Dr. Kress. “This decision was therefore very difficult for us. However, it was necessary to ensure the long-term competitiveness of the MAPAL Group.”

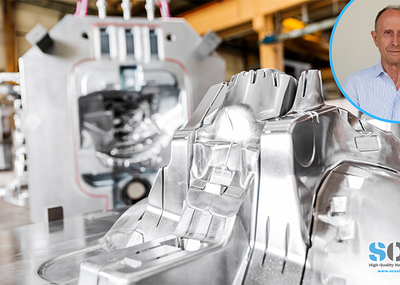

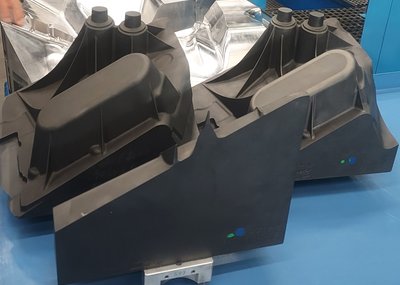

At the same time, the company is implementing numerous initiatives to strengthen its future viability. In the automotive industry, the Generic Component approach is yielding positive results: for strategic components, MAPAL independently develops prototype parts and corresponding machining processes, which can then be quickly adapted to meet individual customer needs. This approach was successfully applied, for example, in collaboration with a machine tool manufacturer to produce stator housings – a key component in electric mobility. MAPAL is also continuously introducing product innovations and process optimizations for all components relevant to metal cutting, enabling customers to realize productivity gains. A case in point: with its HNHX indexable inserts, MAPAL has significantly improved the efficiency of valve seat ring machining in internal combustion engines. In the field of fluid technology, the company is expanding its product portfolio to offer intelligent, combined solutions that better address specific customer requirements.