The Italian company O.M.LER srl is renowned worldwide for decoring solutions for the foundry industry, in particular for gravity, low pressure and lost wax foundries.

In partnership with overseas distributors and agents, and thanks to the expertise of its technical and sales team, O.M.LER markets and sells the pneumatic decoring hammers RVC70 and AF1470. Each is available in three different versions, according to the casting type to decore, both in Western and in Eastern countries.

Besides the pneumatic decoring hammers, O.M.LER designs and manufactures at its Italian headquarters the decoring benches in accordance with the customer’s individual requirements. The decoring benches are designed with the pneumatic decoring hammers fastened in a fixed horizontal or vertical position, depending on the casting type from which the sand core has to be removed. The hammers’ position has to be defined during the design phase, with O.M.LER technical and sales staff continuously interacting and communicating with the client and with the design office, to determine the best decoring solution for the customer.

During the last years O.M.LER’s management, technical and sales staff felt the need to offer something new to the customers. For this reason during last year Covid-19 lockdown period everyone has worked hard to launch in the market a new and innovative decoring solution. From this design effort the new rotating decoring machine DCB18 was borne and now O.M.LER is ready and proud to launch it onto the world markets.

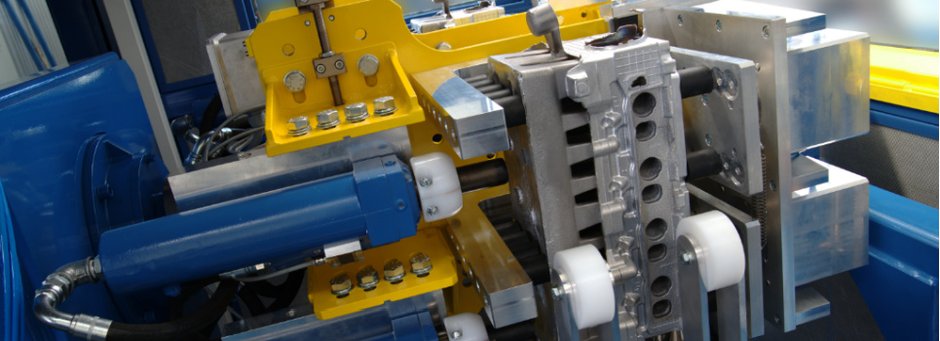

The decoring machine DCB18 is an innovative equipment which allows to remove the sand core from more than one foundry casting simultaneously and it can process cast iron, aluminum and steel castings with a total weight of 70 kilos each, including the sand. Its design has a unique and particular feature: it is able to rotate up to 360° in both rotating directions without interfering or breaking the decoring hammers’ beating action. The machine has been specifically designed for all of O.M.LER’s pneumatic decoring hammer models to fit and be fastened to the DCB18 decoring machine structure.

To warrant and guarantee that the machine complies with environmental safety regulations, the equipment is mounted into a certified soundproof cabin according to the European Regulations EN 1090-1:2009+A1:2011 and UNI EN ISO 11690-1.

Stay tuned to discover more detailed information about the new decoring machine DCB18, O.M.LER will post in the very next future. So watch this space!

In the meantime to get further information about O.M.LER’s decoring machine DCB18 and about the other company decoring solutions, please just contact O.M.LER’s technical and sales staff by phone +39 0172 457256 or per email at omler(at)omlersrl.com .