At EUROGUSS 2026 in Nuremberg, Plasmatreat GmbH demonstrated how atmospheric pressure plasma reliably prepares metal surfaces for subsequent processes such as coating, sealing, bonding, and printing.

From January 13 to 15, 2026, visitors to Hall 6, Booth 219 experienced live how plasma technology is transforming surface treatment – with a clear focus on highly effective cleaning, innovative nano-coatings for corrosion protection, and full inline capability.

Plasmatreat showcased its advanced plasma processes, including Openair-Plasma, HydroPlasma, and PlasmaPlus, highlighting how these technologies enable efficient surface modification while improving process stability and environmental performance.

Removing inorganic residues with HydroPlasma

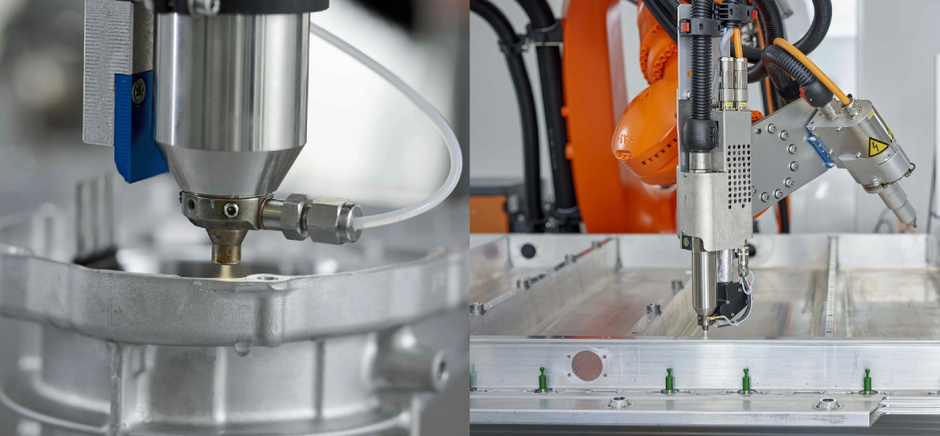

With HydroPlasma, Plasmatreat presented a cleaning process that combines the physical effect of Openair-Plasma with the chemical reactivity of water. During the process, water was fed into the plasma and ionized, creating reactive species that dissolved both organic and inorganic residues and converted them into soluble or gaseous components.

The cleaning effect was comparable to intensive washing with detergent in warm water – but without the use of additional chemical cleaning agents. A key focus of the trade fair presentation was the PTU (Plasma Treatment Unit) type 1212, which demonstrated how workpieces could be effectively cleaned using HydroPlasma.

Live demonstrations where at Booth 219, Hall 6

At a live demonstration table, various aluminum and magnesium sample parts were treated in real time. Visitors were able to directly observe how ultra-fine plasma cleaning significantly improved surface wetting and adhesion.

In addition to live cleaning demonstrations, Plasmatreat presented analysis methods for verifying plasma treatment results. Special attention was given to the AntiCorr test fluids, a fast and innovative test method developed for rapid verification of AntiCorr coatings.

Within seconds, visible and evaluable results were obtained, allowing reliable conclusions about coating quality. This approach significantly simplified and accelerated the evaluation process.

Ultra-fine cleaning with Openair-Plasma – precise and chemical-free

Metal surfaces are often contaminated with release agents, lubricants, cutting oils, or drawing greases from upstream manufacturing processes. These residues must be removed to ensure reliable downstream processing. Conventional cleaning methods typically rely on chemicals, yet residues often remain and impair processes such as bonding, sealing, or coating.

At EUROGUSS 2026, Plasmatreat demonstrated that Openair-Plasma offers a thorough and environmentally friendly alternative to wet chemical cleaning. Using only compressed air and electricity, organic contamination was selectively removed without chemicals. The technology proved to be clean, efficient, inline-capable, and highly targeted.

PlasmaPlus AntiCorr coating – preventing corrosive infiltration

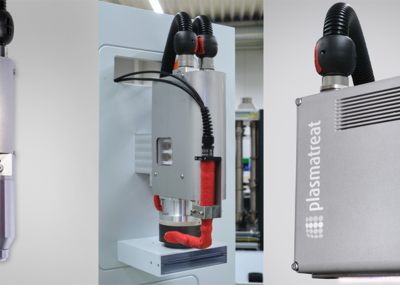

Another highlight was PlasmaPlus, a process that applies a functional nano-coating to metal surfaces. By adding a precursor to the plasma, an ultra-thin and highly effective layer was deposited on the component. Depending on its composition, this layer fulfills specific functions.

The PlasmaPlus AntiCorr process was presented as a high-performance corrosion protection solution, particularly suited as a protective layer beneath housing seals. It effectively prevents infiltration corrosion and protects sensitive electronic components from damage.

A key advantage demonstrated at the trade fair was the selective inline application of the AntiCorr coating, ensuring that only required areas of a component are treated. Compared to conventional corrosion protection processes, this approach significantly reduced chemical usage, logistics effort, time, and costs – while also minimizing environmental impact.

For more information, please visit: www.plasmatreat.com