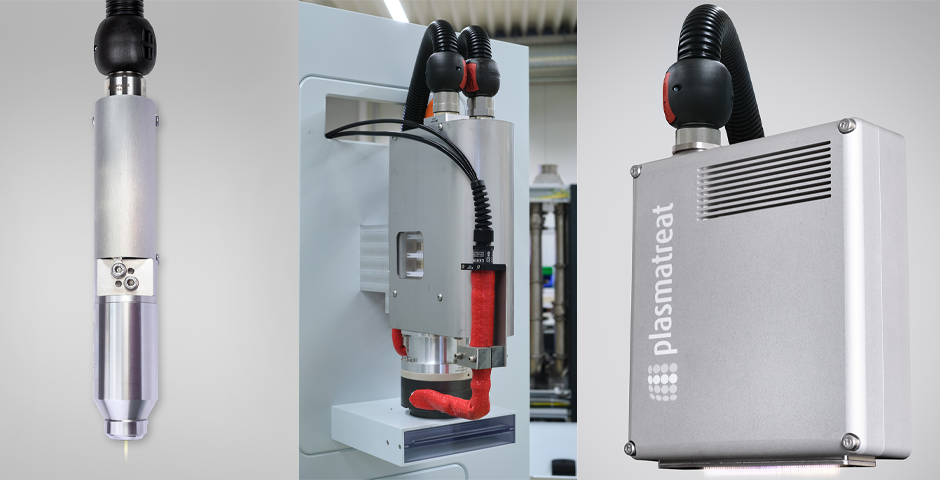

Plasma technology can be used to modify the surface properties of a wide variety of materials in order to optimally prepare materials and material combinations for subsequent processes. Plasmatreat has developed various processes for this purpose: In the fine cleaning of metals or glass, for example, with Openair-Plasma, surfaces are gently and safely freed from dust, grease, release agents and additives. This increases the surface energy and optimizes the wettability of the substrate surface. During activation, the surface of the substrate, e.g. the non-polar plastic, reacts with molecules excited by plasma. In this process, oxygen groups are introduced into the top layer of the plastic, significantly improving adhesion. This makes bonding, painting, printing or gasketing easier - or, in some cases, possible in the first place. For the environmentally friendly pretreatment, plasma is applied to the substrate with pinpoint accuracy using simple compressed air through a special nozzle. One of Plasmatreat's core competencies here is the application-specific coordination of distance, treatment width and traversing speed - and the selection of the right nozzles for the process in question. Another process, PlasmaPlus technology, uses nanocoatings to create functionalized surfaces, such as an adhesion promoter layer or an anti-corrosion coating. Here, a precursor is added to the plasma jet and a nanolayer with the desired properties is then deposited.