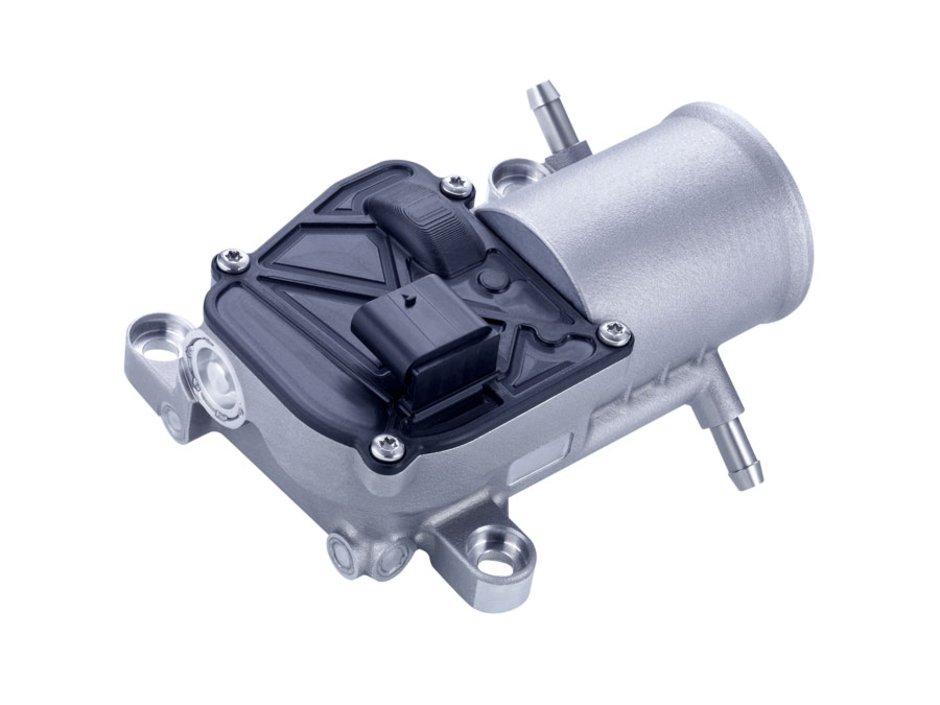

Pierburg presents a new style of wastegate actuator. Among the advantages of the advanced design is an improvement in charge pressure control as demonstrated under operating conditions.

Pierburg's newly engineered wastegate actuator allows direct activation of the wastegate valve by being mounted on the hot turbine housing. Thermal insulation from the housing combined with efficient temperature control of the coolant prevent actuator overheating under all operating conditions. Additionally, the 12-V DC motor (an EC motor is optionally available) is cooled to such a degree that motor load can be stepped up with the advantages of a lower gear ratio between motor and actuator shaft and a higher actuating torque. The shaft can also be completely sealed against the aluminum housing for protection against water splashes without the risk of heat damage. In this way, the system is both robust and very workable.

The design of the actuator and the idea of mounting it on the turbine housing were both originated at Pierburg. An essential aspect of the design was the DC motor which is being built at Pierburg's own motor production facility. For system validation, prototypes were produced and tested on the company's test benches over 500 operating hours on a new gasoline engine shortly to go into series production. The actuator worked to complete satisfaction and demonstrated its stability even under hot-soak conditions. It has now been readied for series production and is currently being examined by a manufacturer of exhaust-gas turbochargers. Besides its wastegate control function, the unit can also serve as an actuator at the bypass on the high-pressure stage of a two-stage charger as well as on commercial vehicles.

Advantages of extended range of settings

For pressure control, modern charge systems use mechatronic actuators which to avoid overheating are in most cases connected to an actuating element via linear kinematics with a heat-insulating function. The disadvantages of the latter are, on the one hand, the high wear rate and audible activation cycles and, on the other, the indirect and hence partly inaccurate position determination of the actuating element. Arrangements with direct coupling of actuator and element avoid these drawbacks while also enabling setting ranges far beyond 90 degrees. This extended range permits a dethrottling of the exhaust system and improvement of exhaust gas aftertreatment during cold starts. These are benefits of substantial significance with the introduction of real-world measurements of emission in place of the ECE standard used so far.

Source: Rheinmetall

Available: <link https: www.foundry-planet.com de equipment detailansicht _top external-link-new-window internal link in current>![]() <link https: www.foundry-planet.com cn equipment detail-view _top external-link-new-window internal link in current>

<link https: www.foundry-planet.com cn equipment detail-view _top external-link-new-window internal link in current>![]()

Partner

Foundry Daily News

Optimum control of charge pressure

Reading time: min

[2]