Ergonomics is concerned with the "fit" between the user, equipment and their environment, is also known as worker factors or human factors. Improving Work Station Design and Working Conditions, in areas of high risk such as heavy manual grinding in a foundry, should lead to significant improvements on bottom line for foundries. Not only gains on the Productivity per worker are common as a result of Ergonomic thinking but considerable Quality and Safety benefits are likely as well. The hidden costs of poor worker engagement and poor worker retention can also improve considerably, requiring much less management time and input into Recruitment, Advertising, Training, Supervision and Inspection.

Are there Bigger Priorities on Cost in the Foundry?

Given that it is generally recognised that often 25%+ of all staff in a foundry can be engaged in grinding, that it is the most dangerous area of foundry, and that 10-15% of total foundry costs can be allocated to the grinding department it is the most obvious and likely to be the most effective place to look to drive lower costs through better Work Station Design and Working Conditions.

The 'ergonomic' principle of fitting the work to the worker rather than forcing the worker to fit the task, particularly in dangerous and labour intensive areas of foundries, such as grinding departments, should be a basic starting point.

Albert Einstein said “ The definition of insanity is doing the same thing over and over again and expecting a different result.”

Why would any foundry want to continually hire employees to do heavy grinding work that may have a high risk factor of Injuries, Musculoskeletal disorders (Vibration White Finger etc.), Noise, Dust that can lead to Lost Work Time, Absenteeism, Injury Claims and Disability Claims?

Some Foundries have a clear vision on Ergonomic Design and Working Conditions of a Grinding Department. Money!!

Immediate Bottom Line Improvements

- Wisconsin Aluminium Foundry in USA, with 360 employees has reduced workers compensations costs after monthly ergonomics inspections by 76.6%.

- Manitowac Grey Iron Foundry's Rob Peaslee of USA states that starting an Ergonomics and Safety Plan has resulted in 36 months without a Lost Time Incident.

- Leading UK foundry Castings plc. has eliminated all claims for Vibration White Finger and has benefited from lower insurance premiums since installing Koyama Automatic Grinding Machines and designing a system to aid worker comfort in loading/unloading/inspecting etc.

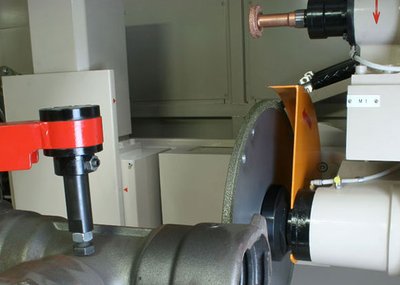

Koyama Work Station Design

- Productivity: 1 machine is 3,4 or 5 times faster than manual grinder, often workers easily work 2 machines

- Safety: Noise, dust, and vibration issues are practically removed from working environment. Accidents to fingers and/or eyes eliminated by fully enclosed operation.

- Working Conditions: Clean safe and much less effort required. Lifting and posture managed better by design of work tables and of the stillages tilted at angle to make picking easier

- Quality: Repeatable every casting not dependent on worker accuracy or lack of errors. Inspection can be eliminated or reduced substantially.

- Scrappage and Reworking: Reduced stress and workload of rejected castings being returned to working cycle

- Human Resources: Less lost hours lost and restricted working conditions. Claims for workers compensation and disability

- Meet Regulatory Legislation: Koyama system reduces greatly management of risks in grinding department whilst meeting (generally avoiding by substitution of manual task for automated process) Health and Safety EU legislation.

- Insurance: Potentially lower insurance costs or reduced premium increase

- Reduce Costs to Stay Competitive

- Start with Largest Problem. The Grinding Department.

- Or is it an Opportunity?