In the welding field, however, some argue that a robot takeover might be beneficial, and even necessary.

Columbus startup Path Robotics believes AI is one solution to the shortage of skilled labor that plagues welding. Path boasts the “world’s first truly autonomous robotic welding system.” Conceived after 18 months in the basement of a foundry, its system identifies what needs to be welded, welds it and learns along the way.

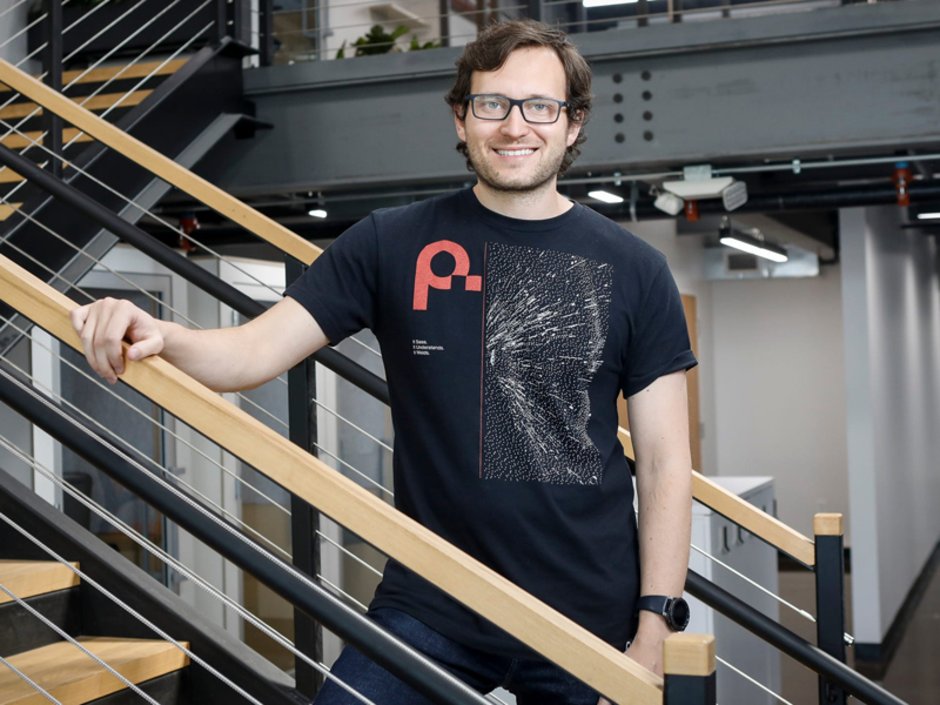

Path Robotics CEO Andy Lonsberry said he and his brother, Alex Lonsberry, chief technology officer at Path Robotics, always wanted to start a business.

“We had a pretty entrepreneurial upbringing,” Lonsberry said in an interview as he talked about his family's custom motorcycle business, which was his start in manufacturing.

While working on their doctorates at Case Western Reserve University, the Lonsberry brothers spent two years searching for an industry problem where they could put their machine skills and entrepreneurial spirit to use.

The process led them to a company struggling to fill welding positions vacated by employees leaving for better-paying jobs.

Skilled labor shortage

This wasn’t an isolated struggle, Lonsberry said. According to the American Welding Society, the U.S. could face a shortage of 400,000 welders by 2024.

Path Robotics is targeting something that Jon Jennings, the marketing director at Edison Welding Institute, said is a challenge for companies of every size.

“Right now, manufacturing is not super sexy. Kids don’t want to go into manufacturing,” Jennings said. “They want to be behind a computer, they want to do other things than go into plants.”

Jennings said that robots aren’t really taking roles from human welders and can actually remove welders from dangerous situations.

Roots in the Midwest

Path Robotics is committed to Ohio and the Midwest. When Lonsberry flew to Silicon Valley to seek funding, it was overwhelming.

“A couple of Ohio boys going out to the West Coast, you never know exactly how it’s going to be taken,” Lonsberry said, adding that he believed having an autonomous robot alongside him didn’t hurt. Path found its seed funding in Silicon Valley from venture capital firm Lemnos Labs.

Columbus venture capital firm Drive Capital came next in the Path Robotics equation with an initial $12.5 million investment, Lonsberry said. Path also more recently raised $56 million in series B funding led by New York City-based venture capital firm Addition Capital. Drive also participated in that round.

Drive Partner Nick Solaro said Path Robotics is one of the most exciting companies in its portfolio.

“Underneath what they’ve built is truly remarkable technology,” Solaro said. “Path Robotics is a software that knows how to learn skills, deeply complex skills, with little to no human input.”

While Path Robotics originally was based in Cleveland. Lonsberry said it relocated to Columbus to be closer to Drive as well as a swath of talent.

“The amount of engineers in this city, and very close to the city, is massive,” Lonsberry said. “We’re certainly hoping to help make Columbus the next big mecca for robotics.”

Staying in Columbus gives Path Robotics a competitive advantage, too, because it places them geographically closer to a big base of customers.

Looking ahead

With more than $70 million in funding so far, Lonsberry said growth for Path Robotics this year will be about growing its team, expanding its facility space to grow manufacturing capacity and delivering on products.

Path Robotics employs more than 100 people, and the company hopes to expand to a staff of 160 by the end of the year. The company website listed 20 openings on Thursday.

Lonsberry said Path Robotics has hundreds of people throughout the United States interested in purchasing its system.

Path Robotics is located in the Scioto Audubon Metro Park and will be expanding its facility to more than 60,000 square feet in the coming weeks.

By the end of the year, the company also plans to release a second manufacturing product, which won’t have to do with welding, according to Lonsberry.

“The first skill their system learned on its own is welding, but that’s not the last thing it’ll do,” Solaro said.

Source: SARAH DONALDSON | The Columbus Dispatch