To promote the digital transformation in these areas, Rösler Oberflächentechnik is developing innovative digitization solutions. The Rösler Smart Solutions activities focus on the comprehensive monitoring and control of work and production processes and the intelligent linking and handling of the respective data. This creates added value for the equipment users and represents an important milestone in the digitization of shot blasting and mass finishing operations. The first digitization packages will be available for commercial use in spring 2021. Further solutions for the equipment portfolio of the Rösler brand “AM Solutions - 3D post processing technology” are already in the planning stage.

Nowadays digitization and intelligently linked work and production processes are hot subjects. Generally, developments in this field are focused on improving quality and productivity within a more flexible production environment, achieving better financial results and generating continued growth. The overall goal is, of course, to make a business more competitive and to make it fit for the future. This trend poses also new challenges for the suppliers of surface treatment machinery. In order to create added value for the equipment users, intelligent solutions must be developed, which – with the use of dedicated sensors – collect and evaluate precisely defined equipment and process data.

The benefits of the Rösler Smart Solutions

To date the available solutions for shot blasting and mass finishing operations were limited to stand-alone systems with no or very limited networking possibilities. To promote the digitization of its own equipment range, the Rösler Oberflächentechnik GmbH is actively pursuing the development of suitable solutions under the trade name “Rösler Smart Solutions”. The company’s ultimate goal is to make processes more transparent and reduce their costs, actively monitor the processes to develop suggestions for specific actions and, on the basis of already archived data, to allow quick correction of deviations and equipment faults. All this is intended to create an intelligent process and equipment control system, which also allows a wide variety of consumption and wear forecasts to be made. Moreover, with the new smart solutions package the company wants to achieve the optimum usage of resources and, thus, contribute to an improved cost-efficiency. Of course, this approach will also help to document all relevant eequipment and process conditions, which is already a requirement in the automobile and aerospace industry as well as for medical engineering companies.

The begin of digitization in the Rösler product portfolio

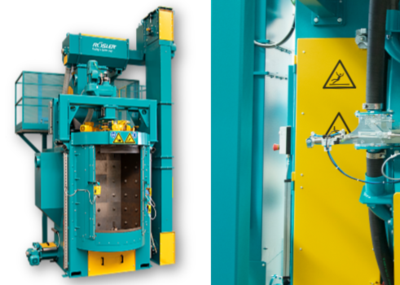

The company intends to quickly implement the digitization of the Rösler equipment range. This will extend to solutions in the fields of mass finishing and shot blasting as well as the Rösler brand “AM Solutions - 3D post processing technology” for the automated post processing of 3D printed components. In a first phase the digitization package for the entire shot blast equipment range will include software and hardware modules in the areas of work piece quality, operating parameters and maintenance. These modules can be used individually or as entire packages and are, therefore, ideal for customer specific digitization strategies. The first solution in the field of mass finishing deals with process water cleaning & recycling with centrifuges. A dashboard will display all relevant equipment and process data, and the user will be able to obtain suggestions for immediate corrective action in case of detected problems or deviations.

All Rösler Smart Solutions described above will be available by spring 2021 and will be regularly updated. They represent only the beginning of further developments in the field of digitization, which will cover the entire equipment portfolio of the Rösler Oberflächentechnik GmbH, including the brand “AM Solutions – 3D post processing technology”.