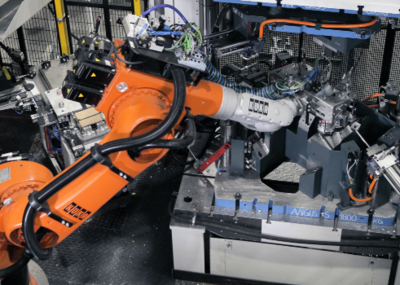

KUKA presents the second generation of KR QUANTEC foundry robots

Flexible, powerful and economical – these are the impressive characteristics of the new KUKA Foundry robots from the KR QUANTEC series. During the past year, the automation specialist completely revised the standard version of its bestselling robot, ensuring that it remains state-of-the-art technology. KUKA is now presenting the second generation of the special version for the foundry, forging and machining industries – more digitalized and even better than before. The 14 different robot types are particularly at home in extreme conditions: from humid, dirty or dusty environments to extreme heat – when the going gets tough, the KUKA Foundry robots of the KR QUANTEC series really get going.

Optimized portfolio for maximum flexibility and short delivery times of foundry robots

KUKA has significantly expanded the performance range of the foundry robots. All 14 Foundry variants have protection rating IP67 as standard – for the entire machine. They effortlessly withstand ambient temperatures of up to 55 °C. The robot wrist can even withstand a maximum temperature of 180 °C for ten seconds per minute, which is enormously advantageous when reaching into a furnace, for example.

“Our robot thus offers customers in the foundry, forging and machining industries greater application flexibility – as does the option of upgrading the payload capacity in the field. Furthermore, it boasts outstanding values for total cost of ownership (TCO),” says Wolfgang Bildl, the responsible product manager at KUKA.