Finding the solutions of the future – this is what EUROGUSS, Europe's largest trade fair for die casting, promis-es its visitors. From 14 to 16 January 2020, visitors to Nuremberg will be able to convince themselves which solutions KUKA has to offer to support the industry. The robotic and automation specialist’s booth can be found in hall 7A, booth 541.

Precise, fast and durable: KUKA presses for the foundry sector

One of the most difficult and costly tasks in die casting is deburring. For this task, KUKA has an efficient and cost-effective trim press in its portfolio which can be directly inte-grated into a die casting cell. KUKA's sliding/tilting trim presses are characterized by even more efficiency in deburring of castings and a very user-friendly operator control. Fea-tures such as the drive concept, Dialog IV controller, simple programming and intuitive touch operation ensure process-reliable automation and a high degree of flexibility in the configuration of casting cells. With the series of fast trimming presses, KUKA also has the ideal solution for the increasing demands of production.

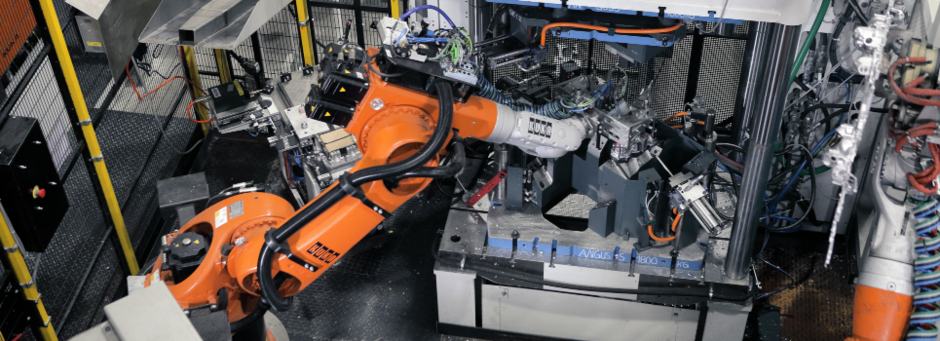

Flexible and reliable deburring with the KUKA Pre-Machining Cell

A KR 160 nano robot deburrs cast components in the automated Pre-Machining Cell. Feeder, shape division burrs and gates can thus be removed. A further advantage: flexi-bility. The built-in turntable places components of different shapes and sizes in the pre-ferred position. The results are cast products of a very high and consistent quality. In addition, the changeover to automated production relieves the strain on people and is more economical than conventional manual work.

Software for die-casting systems: automation from a single source

KUKA offers die-casting automation solutions from a single source, from robots to sys-tem planning. That is why KUKA offers not only an entire robot portfolio for foundries, but software solutions such as KUKA.Sim as well. System layouts can be simply, quickly and efficiently created by using this simulation and offline programming software. In collaboration with Visual Components, KUKA can simulate a die-casting shop fully in 3D which customers can then experience in virtual reality.

Industrie 4.0: minimizing downtime, increasing productivity

In the foundry industry too trends such as digitalization, networking and smart produc-tion are playing an increasingly important role. KUKA offers KUKA Connect, a cloud-based software platform that allows customers to access and analyze the data of their KUKA robots from anywhere at any time.