Die casting machines also need cleaning and maintenance when in use. If left unwashed for a long time, they can easily rust and become dull and difficult to use. Let's talk about the importance of maintenance to Zhejiang die casting machine manufacturers. That is to say, the clamping force is an important parameter to consider whether the design of the clamping mechanism is reasonable. Practice has proved that if the design is reasonable, this kind of mechanism can better meet the working requirements of the die-casting machine.

It's hard to guarantee that every device will work in a good environment. Sometimes some customers only focus on using and making money, often ignoring important maintenance issues. When there is dust, putty, aluminum and other impurities on the equipment, if it is not cleaned in time, the movable template will wear out during movement. After the equipment is worn, it is easy to rust, and the service life will be greatly shortened.

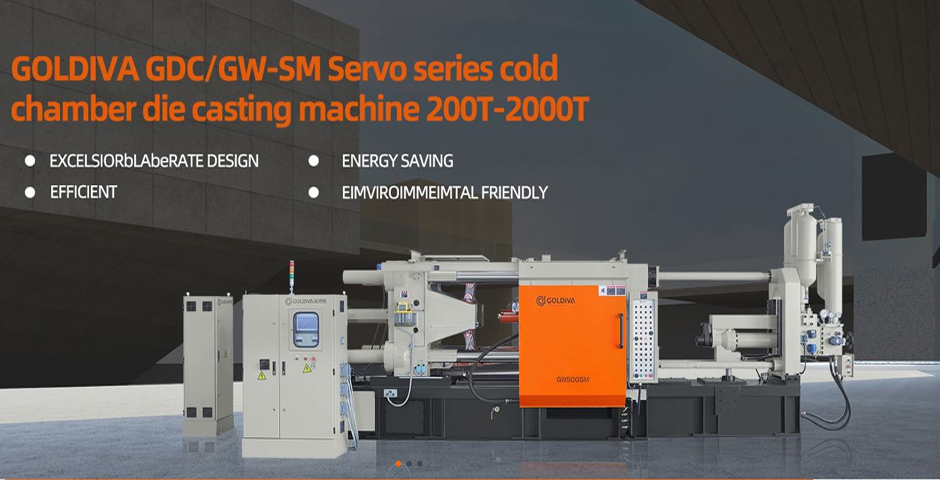

The structure of the die-casting machine clamping mechanism has a great influence on the production efficiency of the die-casting machine, the working conditions of the mold, the quality of the castings, and the labor intensity of the workers. Therefore, the clamping mechanism is one of the important parts of the die casting machine. Most of the die-casting machine clamping mechanisms produced in my country are composed of a clamping cylinder and a double-toggle hinge mechanism (machine hinge). The combination of the two has a decisive influence on the clamping force.

The clamping mechanism of the die casting machine is equipped with a device for ejecting the casting. (Called the ejector) Generally, the die-casting machine adopts a hydraulic ejector, which is installed on the back of the movable plate, connected by a power cylinder and connected by the top plate. There are many thimble holes on the top plate, which correspond to the holes on the movable plate, which is convenient for the mold to choose the appropriate thimble position.