Thixomolding: An almost forgotten technology is on its way to revolutionize the production of lightweight structural components.

Thixomolding State of the art

Thixomolding Technology is not a new technology, it is based on the processing of magnesium in a semi-solid state and has been used for decades, especially in Asia, for the production of thin-walled components in the electronics industry, e.g. laptops and displays. It is therefore not surprising that most of the Thixomolding machines, around 2.000 machines, are installed in Asia.

The reason that this technology has so far only been used for thin-walled components is that until 2019 this Thixomolding machine was only available with clamping forces of up to 1.000 tons and screw diameters of 84 mm and thus with shot weights of max. 1.500g and throughputs of approx. 80kg per hour.

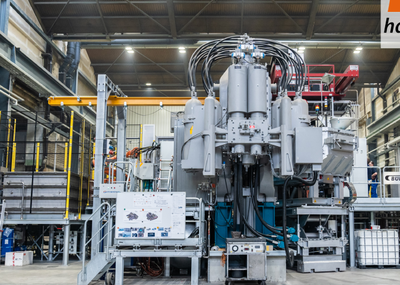

Since 2019, ever larger machines with clamping forces of now up to 6.000 tons and screw diameters of currently up to 190 mm with maximum shot weights of up to 22kg and possible throughputs of 500kg per hour have been developed and launched on the market.

BOLE Intelligent Machinery is one of the pioneers in these further developments and currently has the largest Thixomolding machine in series production on the market, the MTX 4000 D-170 series machine

Magnesium the infinitely available material on our planet

Why does BOLE now rely on magnesium in combination with Thixomolding Technology?

In contrast to many other materials such as plastic and aluminum, magnesium is an infinitely available material on our planet.

Magnesium is a lightweight construction material which, in contrast to aluminum and plastic composite materials, enables a weight reduction of between 10% and 20%.

Magnesium Co2 footprint lower after all?

If you look at the CO2 footprint of magnesium compared to aluminum, there is a big difference per kg.

Aluminum in Europe = 6.7 Co2/kg

Aluminum global average = 15 - 16 Co2/kg

Magnesium Pidgeon process = 22 Co2/kg

But if you have a 1,000cm³ component in die casting with aluminum with 2.7kg at 40.5 Co2/kg and in magnesium with 1.7kg at 37.5Co2/kg.

That is a Co2 reduction of -8%.

If you now take a close look at the CO2 footprint in production and then also consider the thixomolding technology, the following emerges.

In the Thixomolding process, the sprue and overflow weight is between 25% and 40% of the weight of the molded part, which is at least 50% less than in die casting.

If you now look at the Co2 footprint on the shot weight of the 1.000cm³ component mentioned above, you come to the following comparison.

The casting in aluminum with at least 5.4kg at 81.0 Co2/kg and in magnesium with 2.12kg at 46.6 Co2/kg.

This is a Co2 reduction of - 42% compared to the global Co2 average of aluminum.

With new pidgeon processes and electrolysis it will be possible to achieve 8kg Co2 /kg for magnesium in the next few years, then the differences will be dramatic in the future !!!!

Recycling magnesium

As already described, one of BOLE's core strategies is recycling. It is therefore not surprising that we have also tested the direct recycling of start-up parts, sprues and overflows.

The results are that when this magnesium recyclate is fed back into the Thixomolding process, there is no change in the performance of the components.

With this knowledge, Thixomolding is the only process that offers the possibility of a closed material cycle in your company, which again significantly reduces your costs and CO2 footprint.

With its Thixomolding Machine Technology, BOLE also offers its customers a recycling technology that produces the recyclate with minimal energy input and feeds it back into the machine. The customer can decide how much recyclate he wants or is allowed to use in his components.

But as I said, 100% recirculation of your start-up parts, sprues and overflows will have no effect on the performance of your magnesium components.

The general advantages of this Thixomolding Technology are brief.

-

Lower porosity on the components, as shrinkage is very low due to the lower input temperature of 580 to 630°C for magnesium

-

No air inclusions, as the components are coated with a honey-like melt with flow front velocity in the source flow.

-

Better corrosion resistance, due to the lower flow front speed, a closed surface is achieved during thixomolding under pressure in the casting process.

-

At least 20% and in some cases 40% better mechanical values, such as elongation and tensile strength on the component.

-

Energy cost reduction of at least 55% compared to die casting processes. The average energy consumption, including melting and complete peripherals, is less than 0.5 kW per kilogram of magnesium cast.

-

The service life of the tools is at least twice as long and in some cases up to a factor of 3 compared to production using the die casting process. This is a massive cost reduction, especially in the area of large components and therefore tools.

Component costs

If one now compares the article costs in the production of magnesium components in die casting exactly with the production of the same component in Thixomolding, the manufacturing costs in the Thixomolding process are generally 21% to 23% lower, depending on the component.

If you now compare the longer tool service life and the cleaning intervals, you arrive at 26% to 28% lower costs.

When using BOLE recycling technology in combination with a Thixomolding machine, we achieve almost 35% lower manufacturing costs for your components.

Conclusion

We at BOLE Intelligent Machinery are firmly convinced that we can make our planet a little better with Thixomolding Technology.

We would be delighted if you could lead the way in this project together.

We will provide you with more information on the topic of Thixomolding in the near future on Foundry Planet with the hashtag "What the Hell is Thixomolding".