YXLON has introduced a new X-ray system for the aerospace market based on the proven design of the universal Y.MU2000-D inspection system. Thanks to its well-engineered concept, the new YXLON MU60 AE is the fitting solution for ensuring quality of a large variety of parts while meeting the latest aerospace industry standards.

The new MU60 AE x-ray system meets the relevant ASTM standards and MAI guidelines, is DICONDE compliant, and supports Nadcap certification with tools such as the automatic system tests per ASTM E2737. As a result of intelligent inspection workflows controlled via the wellestablished PXV500 software, the MU60 AE is well suited for spot-check sample inspection, series inspection and 100% inspection during continuous operation by utilizing both manual and automatic inspection modes. For easy traceability, a bar-code reader for part identification is integrated as well.

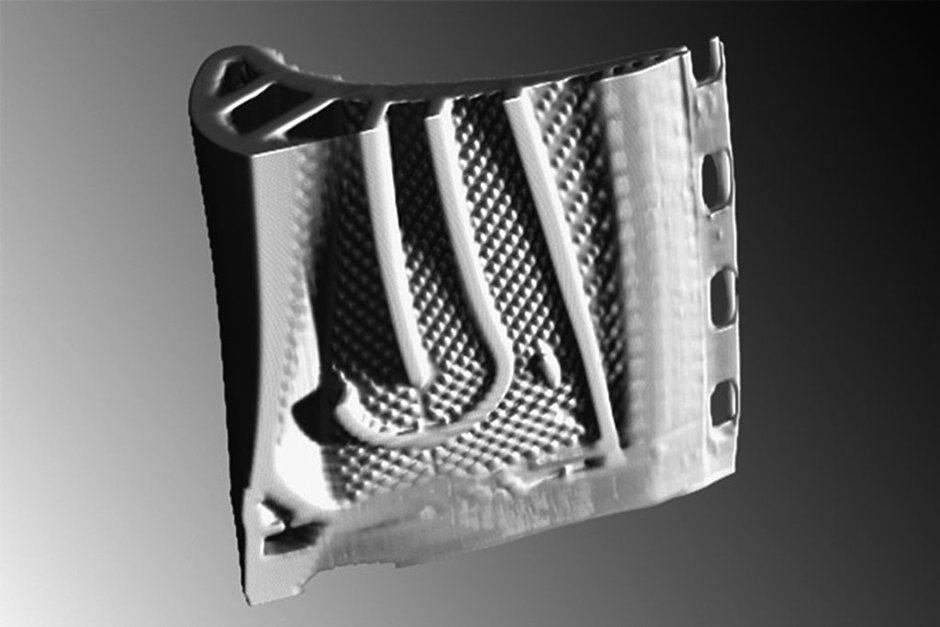

Complicated and time-consuming part fixtures can be reduced or eliminated due to the proven manipulator design. The part turntable moves and rotates in the horizontal plane, while the x-ray tube and detector are mounted on a U-shaped arm that moves in the vertical direction. An optional turntable tilt axis that provides even more flexibility for the respective inspection tasks is available as well.

Industry-leading image quality is achieved using the YXLON Variofocus tube, the highperformance Y.XST x-ray generator, and the HDR Premium digital detector. Together with the Y.Image 3500 image processing software, the PXV5000 control software enables preprogramed, automated inspection workflows, fast image generation, and precise inspection results. Y.AdResult, an archiving and analysis software, is optionally available as well. With its help, digital images, data and even complete inspection programs can be archived quickly and efficiently, and even made available to other locations via networking or cross-linking. In addition, production statistics and analyses enabling consistent process improvement can also be provided.

When the situation calls for it, separate Offline Review Stations can also be implemented to offer special convenience. These stations make it possible to evaluate inspection results independently of the inspection system involved – giving optimum flexibility to the inspection team.

As an additional technology option, Computed Tomography (CT) functionality can be easily integrated with this system. Using YXLON’s superior image acquisition, combined with the latest software packages from Volume Graphics, many advance inspection tasks such as geometric measurement and material analysis can be performed.

The concept and performance capability of these x-ray inspection systems specifically designed for the aerospace market has already convinced leading companies in the aviation industry. One such company promptly commissioned an order for two systems in the United States, and more are sure to follow.

auch verfügbar in: <link record:tt_news:14137 internal-link>![]()

![]()

###COMPANY_LINK### <link record:tx_browserdirectory_directory:4192 internal-link>![]() Yxlon International GmbH

Yxlon International GmbH