The applications for Walther Trowal mass finishing systems are very diverse. The technology is equally effective for deburring turbine blades for jet engines, deburring and edge radiusing of stampings for the automotive industry and finishing of orthopedic implants for medical engineering.

Small work pieces: Surface smoothing, polishing and drying in one single finishing system

The new TT Turbotron centrifugal disk finishing machine from Walther Trowal allows the surface smoothing and polishing of small work pieces in one single machine. This helps to significantly streamline a broad range of surface finishing operations. The TT 280-A/2C operates fully automatically – from loading the raw work pieces into the processing bowl to discharging the polished and dried components. A typical application is the finishing of piston rods used in dampening systems for hinges, for example, in kitchen appliances, such as ovens and dishwashers, and furniture doors.

Big components: Finishing times reduced from days to just a few hours

The new Multivibrator MV 50 is the largest of this machine type ever built by Walther Trowal. It cuts the cycle time for finishing the surface of big components from several days to just a few hours. With an internal diameter of the processing bowl of 1,600 mm this machine allows the fully automatic surface finishing of components with a diameter of up to 1,300 mm in one single operation. For example, the MV 50 can handle extremely complex components utilized in jet engines and wind power turbines. It is equally suitable for finishing turbine disks, blisks and forging tools. The first MV 50 system is about to be delivered to a customer in the aerospace industry.

Solutions for a broad spectrum of surface finishing tasks

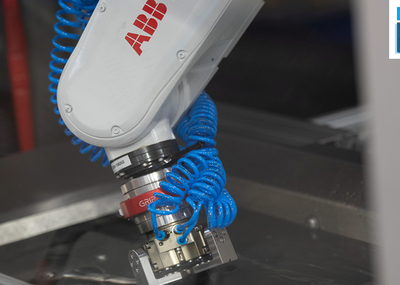

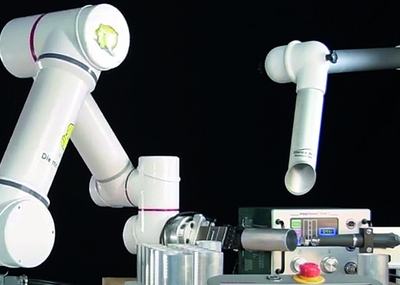

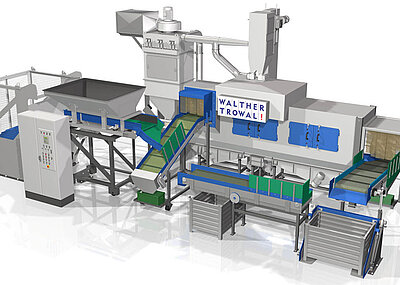

The mass finishing equipment program at Walther Trowal ranges from stand-alone rotary vibrators to fully automatic finishing systems that include work piece loading and unloading devices. They can be easily integrated into continuous flow manufacturing operations. The company utilizes a broad range of grinding and polishing media, for example, specially developed grinding media that allows the effective deburring of work pieces without removing too much material from the work piece surface. Especially in the case of components with complex shapes and internal passages, such as undercuts and drilled holes, the media allows the finishing of surface areas, which would not be possible with manual deburring.

About Walther Trowal Surface finishing technologies from the inventor of the “Trowalizing” process

Since 1931 Walther Trowal has been developing and producing systems for the refinement of surfaces. Initially focusing exclusively on mass finishing – the term “Trowalizing” originated from the company’s cable address “Trommel Walther” – Walther Trowal has continuously expanded its product portfolio.

Over time the company has developed a broad range of machinery and systems for mass finishing, shot blasting and coating of mass-produced small components.

With the invention of new systems like, for example, drag finishing and the development of special finishing methods for 3D printed components, the company has proven its innovative capabilities again and again.

Walther Trowal develops and implements complete surface treatment solutions that can be seamlessly integrated into linked production systems existing at the customers. This includes the entire process technology, perfectly adapted to the specific surface finishing requirements of the work pieces: Equipment and the respective consumables always complement each other in a perfect manner.

Each individual work piece and each manufacturing process must meet special technical requirements. That is why the experienced process engineers in our test lab, in close cooperation with the customers, develop the optimal process technology for the finishing task at hand. The result: Work piece surfaces that meet exactly the required specifications … with short processing times and a high degree of consistent, repeatable results.

Walther Trowal is one of the few manufacturers who develops and produces all machines and mass finishing consumables in-house … including ceramic and plastic grinding and polishing media as well as compounds.

The company’s equipment range also includes all kinds of peripheral equipment for handling the work pieces like lift and tip loaders, conveyor belts and roller conveyors, in addition, special driers for mass finishing applications and, last-but-not-least, systems for cleaning and recycling of the process water.

With its exchange program for wear items like work bowls, which are part of a continuous recycling program, Walther Trowal conserves valuable resources and, thus, makes a significant contribution towards sustainability in the field of industrial production. Quick technical support and the global repair and maintenance service ensure high uptimes for our equipment.

Walther Trowal serves customers in a wide range of different industries all over the world, for example, automotive, aerospace, medical engineering and wind power.