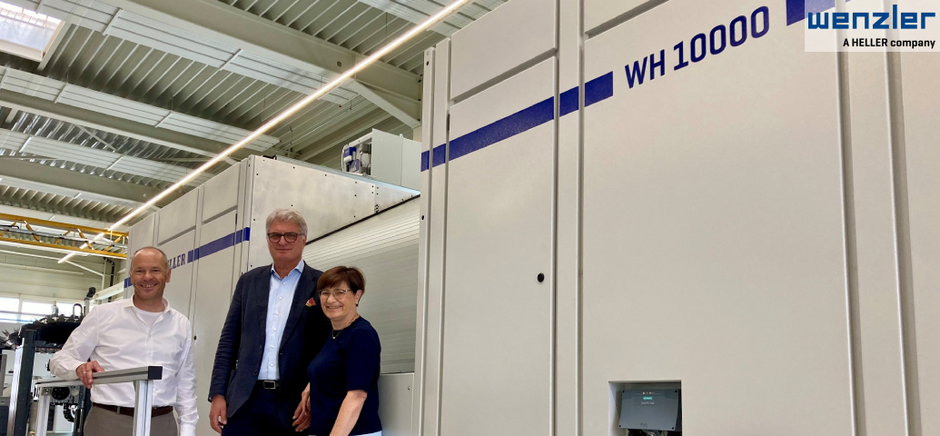

Foundry-Planet on Tour at Wenzler in Spaichingen. In conversation with managing director Wolfgang Wenzler and Ingrid Wenzler, one central topic took center stage: the optimization of the entire value chain in machining technology.

Wenzler has been part of the HELLER Group since 2009 and, as such, is responsible for the machining of aluminum structural parts. Wenzler therefore has access to the HELLER modular system and benefits from the global presence of the HELLER Group and its service network.

Unlike many of its competitors, Wenzler sees itself not only as a machine supplier, but also as a partner that delves deep into the processes and considers the interaction between foundry, machining, and OEM in detail.

This is particularly evident in the company's approach of not viewing the value chain in isolation, but always considering the steps before and after machining. Consistent references and alignments in the manufacturing process are crucial to avoid machining errors. Wenzler relies on close cooperation with tool manufacturers and suppliers, goes into the details of drilling and milling technology, and consistently works with minimum quantity lubrication (MQL) to ensure process stability and sustainability.

An important factor for success is the experience and knowledge of the employees: Many processes are literally assessed “by ear.”

Since the machines are extremely stable in design and have excellent damping properties, process noises can be precisely identified and reliably verified based on 20 years of experience with aluminum structural parts. The insights gained are then incorporated into the adjustment of process parameters, tool designs, and clamping strategies.

Wenzler is therefore committed to systematic knowledge management in order to make empirical values from projects permanently usable—a weak point that is often lacking in large suppliers.

Wenzler also sees considerable potential in the interaction between foundry and machining. Although foundry operators often claim to be able to work with minimal allowances, practice shows that material properties and machinability vary greatly, even with identical alloys. Closer, early cooperation could bring enormous efficiency gains here. Wenzler's appeal is clear: the value chain must be understood holistically and coordinated across company boundaries