Conventional construction of modern vehicles involves the assembly of myriad sections of stamped sheet metal that are joined together by welding, rivets, and epoxy to form the chassis structure of the car’s platform.

New cars like the Tesla Model 3 from the company’s German plant, the Maserati Grecale SUV, and the next generation of Volvo EVs depart from convention by building the cars atop just a few very large, very complex aluminum alloy castings. These bolt together to form the entire chassis, with front, center, and rear sections that replace, in Tesla’s case, 370 discrete parts that would need to be joined together to form the car’s chassis.

“Using a simple casting to replace assemblies is something that is quite common and there are a whole bunch of reasons why that is becoming far more prevalent,” noted American Foundry Society vice president of metalcasting technical services, Brian Began.

Global Industry Analysts, Inc. forecasts in a report on the industry that the global market for all types of die casting will total more than $100 billion by 2026, from $76.4 billion in 2022. “Demand for passenger cars and light commercial vehicles across the globe, more so importantly in developing markets, will especially drive robust demand for use of cast products for a range of automobile parts and components in the coming years,” the report explains. “The market is also expected to benefit immensely from the shift towards aluminum over steel and iron products among automakers.”

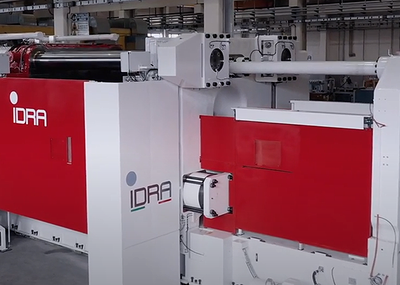

Tesla employs a casting press from Italian specialists Idra which that dubs a “gigapress” because of the very large size and high pressure employed, creating what Tesla calls a “megacasting” to form the Model 3’s platform.

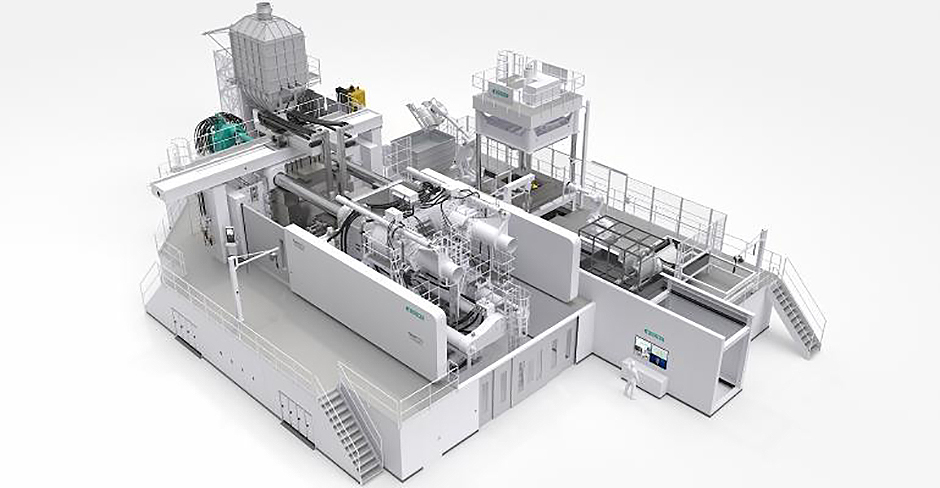

Volvo’s press, from the Swiss company Bühler, doesn’t have a catchy name (they have the Carat 840 and 920, which operate at pressures of 84,000 kilonewtons and 92,000 kN, respectively) but the company does employ the term “megacasting” to describe the resulting products from these presses. Volvo has installed two Carat 840 presses in its Torslanda, Sweden plant.

Maserati, on the other hand, uses more traditional casting techniques for the Grecale’s chassis, so that company says these are large-scale castings, but not “megacastings.”

Volvo’s casting press supplier Bühler describes the benefits of using large-scale castings in cars on its web site. “New large die-casting solutions now make it possible for a whole body-in-white section to be created as a single piece, allowing automotive OEMs to simplify production, reduce costs, and create a more sustainable vehicle,” the company explains.