YXLON has developed a groundbreaking new solution for more efficient, non-destructive testing of large, flat objects using digital laminography. This marks the latest step in the rigorous implementation of the company’s strategy to extend its market leadership. The innovation opens up new testing possibilities and strengthens the COMET Group’s leadership in the field of X-ray technology.

With a new, innovative process, YXLON has successfully realized a globally unique solution for investigating large, flat objects with extreme accuracy. The system developed by CT experts at the Hattingen location has been filed for patent and opens up access for YXLON and the COMET Group to a new range of possibilities and markets.

With a new, innovative process, YXLON has successfully realized a globally unique solution for investigating large, flat objects with extreme accuracy. The system developed by CT experts at the Hattingen location has been filed for patent and opens up access for YXLON and the COMET Group to a new range of possibilities and markets.

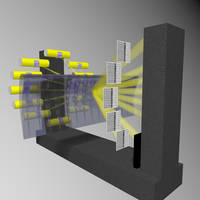

Laminography is a special X-ray technique, somewhere between a simple X-ray and computer tomography. Its applications include testing multilayer boards in electronic components. Thanks to YXLON's innovation and the use of the high-power, high-energy X-ray source developed by COMET (600 kV), laminography can now be applied to large components with complex shapes.

The first laminography system was supplied to China for testing parts used in the aerospace industry. This system makes it possible to detect structures measuring only a fraction of the diameter of a human hair on components with a size of several square meters. The method could also hold promise for other applications, such as the testing of plug-in contacts in oversized component carriers of printed circuit boards (PCBs) or for detecting production faults and signs of wear and tear in the rotors of wind turbine generators.

"With our innovative process in the field of laminography, the COMET Group has achieved a significant technological step forward that makes us unique throughout the world," says COMET Group CEO Ronald Fehlmann. "The innovation is a further step in the implementation of our strategy and shows how we can build on our position as an innovative technology and market leader and inspire our customers."

"With our innovative process in the field of laminography, the COMET Group has achieved a significant technological step forward that makes us unique throughout the world," says COMET Group CEO Ronald Fehlmann. "The innovation is a further step in the implementation of our strategy and shows how we can build on our position as an innovative technology and market leader and inspire our customers."

Laminography:

Laminography is a particularly efficient, reduced form of 3D X-ray testing. Unlike with conventional computer tomography, an object is X-rayed from only a few different angles. The individual pictures produced are combined with each other to form a highly accurate three-dimensional picture of the object.