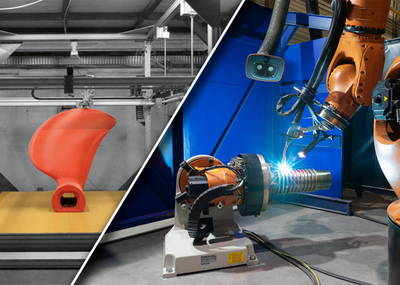

It's every foreman's nightmare: when repositioning a bulky component, it tips over and, in the worst case, injures an employee. If unsuitable equipment such as forklifts or cranes are used, this risk should not be underestimated, as the load is rarely evenly distributed in practice. Added to this is the effort required for the turning process, which increases steadily with the size and irregularity of the component and quickly becomes an energy and time waster. The modular Giromatic from Dumeta provides a remedy: the professional turning device can be attached to conventional load lifters and uses tear-resistant slings or chains to keep a firm grip on objects that are difficult to balance in any position. Depending on the size and weight of the component, the system runs on a turning traverse or a drive unit can be coupled with corresponding travelling units. Even very bulky components can be turned in just a few minutes. For flexible use on cranes and outdoors, the manufacturer now offers versions with exchangeable batteries that do not require a power connection.

"Many companies underestimate how much time it actually takes to handle heavy components and the risks associated with using unsuitable equipment," says Dumeta Managing Director Ivo Mulders. "Often, either emergency solutions have to be constructed or heavy equipment has to be procured and set up at great expense of time."

For example, if the production facility only has a forklift truck or an industrial crane, particularly bulky and heavy components cannot be turned at all or only under very unsafe conditions. If they slip off the fork or out of the temporary turning device on the crane, workers can be injured and damage can occur in the hall and to the component. In addition, the weight of many loads is unevenly distributed due to their dimensions. If the centre of gravity is not determined correctly in advance, the component can tip out of the lifting device during the turning process or move in an uncontrolled manner. Even if the lifting process is carefully prepared, there is still a residual risk.

"You can easily minimise these risks from the outset - and save time at the same time - by using professional turning devices," says Mulders.

Turning device brings unbalanced loads into equilibrium

With Dumeta's modular Giromatic system, a suitable turning device is used depending on the length and weight of the load. To this end, the company checks the planned place of use in advance. For example, a model can be selected for operation with two cranes, whereby two motor units can be used instead of one motor unit and one travelling unit, over which the load-bearing slings run. "When handling certain components, two cranes are required simply because of their weight of up to 100 tonnes and their enormous length of over 60 metres, as otherwise it would be difficult to determine the lifting point and an unstable situation would arise," explains Mulders.

The individual tensile units or the traverse are attached to the crane hook and the workpiece is placed in the turning loops. This makes it easy to turn square parts as well as sharp-edged and eccentric components with high loads within a few minutes. The variant with two driven units is advantageous if more grip is required on each sling or if the load is no longer levelled. In this case, the centre of gravity of the component changes unevenly during assembly - for example, when axles are added to a truck chassis. Thanks to the dual control, the same traction can be achieved on both sides and smooth and even turning can be achieved.

Battery version for even more flexibility

The Giromatic is compatible with all commercially available crane types. "Regardless of the version selected, the focus is on simple and safe handling," explains Mulders. "All turning devices can be operated from a safe distance using a radio remote control." Once the component is in the slings, which are guided to the load either open or closed, it is lifted and rotated until the correct alignment is achieved. Depending on the crane type, power is supplied via a connection directly on the hook or crane arm. Alternatively, the different Giromatic versions are also available with exchangeable batteries, so that the system can be used anywhere without its own power supply. "We developed the battery version last year after our customers increasingly requested such a mobile solution," adds Mulders. "As each turning process is completed within a few minutes, a battery module with a continuous battery life of around 45 minutes is enough for most companies for the entire working day."

Dumeta also advises on the right choice of material and the design of the loops as an open or closed variant. Due to their sharp edges, some components require additional edge protection to prevent damage to the lifting system or the load itself. For these applications, the company offers specially coated slings that are provided with a PE coating and are therefore particularly resistant. The machine manufacturer emphasises a close exchange of experience with its customers.

"If we know where there is a need and what specific problems arise in the application, we can realise customer-specific special designs and constantly expand our portfolio. After all, there are enough problems - we take on the challenge and find the solution," summarises Mulders.

Further information at: https://www.dumeta.de/