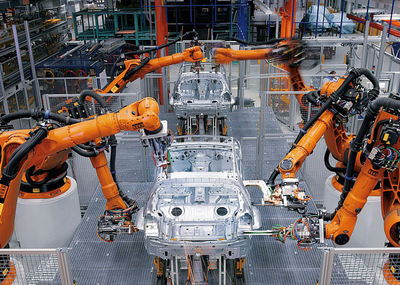

The foundry and forging industry is undergoing a significant transformation, thanks to the advent of automation and robotics. This revolution is not only enhancing efficiency and productivity but also improving safety and quality in the sector. The integration of automation and robotics into the foundry and forging processes is a game-changer, marking a new era in the industry.

Traditionally, foundry and forging processes have been labor-intensive, involving a high degree of manual work. Workers were required to perform tasks such as molding, casting, and forging, often under harsh and hazardous conditions. However, the introduction of automation and robotics is changing this narrative. Robots are now taking over tasks that were once performed by humans, reducing the risk of accidents and injuries, and ensuring a safer working environment.

Automation in the foundry and forging industry is not just about replacing manual labor. It’s about enhancing precision and consistency in the production process. Robots are programmed to perform tasks with a high degree of accuracy, reducing errors and waste. This precision leads to improved product quality, which in turn increases customer satisfaction and boosts business performance.

Moreover, automation and robotics are driving efficiency in the foundry and forging industry. Robots can work round the clock without breaks, significantly increasing production rates. They can also handle multiple tasks simultaneously, further boosting productivity. This increased efficiency translates into cost savings for businesses, making them more competitive in the market.

The integration of automation and robotics in the foundry and forging processes also opens up new possibilities for innovation. With robots, complex and intricate designs can be achieved, which would be difficult, if not impossible, with manual labor. This capability allows businesses to offer unique and customized products, giving them a competitive edge in the market.

However, the transition to automation and robotics is not without challenges. There are concerns about job displacement, as robots take over tasks previously performed by humans. Training and upskilling of workers is also required to operate and maintain these automated systems. Despite these challenges, the benefits of automation and robotics in the foundry and forging industry far outweigh the drawbacks.

The adoption of automation and robotics in the foundry and forging industry is a clear indication of the sector’s commitment to innovation and progress. It’s a testament to the industry’s resilience and adaptability in the face of changing market dynamics and technological advancements.

In conclusion, the revolution of automation and robotics in the foundry and forging industry is a transformative force, driving efficiency, safety, quality, and innovation. It’s a trend that is set to continue, shaping the future of the industry. As businesses embrace this revolution, they are not only enhancing their operational performance but also positioning themselves for success in the increasingly competitive global market. The integration of automation and robotics in the foundry and forging processes is indeed a game-changer, marking a new era in the industry.

Source: www.fagenwasanni.com