The OMEGA SINTO FOUNDRY MACHINERY Support Team may be working from home, but they all have full access to support documentation, and are available to you with the same level of service as before. They are also still making UK site visits where absolutely necessary. As long as Government advice is strictly respected, Omega is proud to be supporting those of you who have risen to the challenge of staying operational throughout this difficult time.

However, if you have had to stop production for a period of time whilst some adjustment was made or social distancing was not possible, Omega is here for you also. Please find attached their recommended start up checks for their most popular Omega Sinto foundry machines. The checks may also be of use to you on any similar non-Omega Sinto machinery that has been out of use for some time.

For any assistance or further information, or to book your summer shutdown service, please don't hesitate to get in touch with OMEGA SINTO FOUNDRY MACHINERY via email at support(at)ofml.net or by telephone.

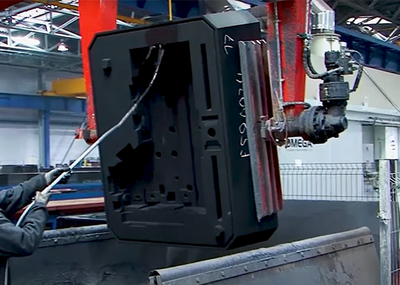

MIXER

- Check all safety systems and interlocks are working correctly and reset ok

- Check the chemicals are still in date and ready to use

- Check there are no flake or debris deposits in all chemical tanks, filters and strainers

- Check the pipelines, filters and sieves for leaks and security

- Calibrate the chemicals checking NRV operation, motor rotation and speeds

- Ensure the mixer is clean and ready for use

- Check all services, air, water electric for correct operation, clean filters as required

- Check sand flow and calibration of each sand

- Lubricate bearings and slewing rings

RECLAMATION

- Check all safety systems and interlocks are working correctly and reset ok

- Check all services, air, water electric for correct operation, clean filters as required

- Check all reclamation is clean and free from sand

- Check all sand flows and remove any old sand that may have absorbed moisture

- Remove inspection covers and check all screens and wear plates are in good order, replace, repair as required.

- Lubricate all points as per the maintenance procedures

PRESSURE VESSELS

- Check all services, air, water electric for correct operation, clean filters as required

- Check butterfly and piston valves for operation and sealing

- Check blow lines for leaks on first blows to all hoppers

DUST EXTRACTION SYSTEMS

- Check all safety systems and interlocks are working correctly and reset ok

- Check all services, air, water electric for correct operation, clean filters as required

- Check filter media for any cleanliness and moisture build up, clean/replace as required

- Check +ve and -ve pressures and DeltaP points, where applicable check LEV flows

- Check dump valve/rotary valve operation

COOLING SYSTEMS

- Check all safety systems and interlocks are working correctly and reset ok

- Check all services, air, water electric for correct operation, clean filters as required

- Check systems for any leaks and top up as required

- Check correct dosing for legionella and antifreeze/rust prevention as required