Toyota recently lifted the veil on some of its objectives for the future when it invited a handful of journalists to tour its Japan facilities and speak with engineers.

The automaker has pledged to sell 1.5 million EVs annually by the decade's end. Despite this being a small fraction of what its peers are putting out or planning to, Toyota seems to think that slow and steady may win the race from a battery technology standpoint.

Earlier this year, the company revealed that it was developing solid-state technology that it said would greatly improve range, charging time, and price.

During the media tour, according to Bloomberg, engineers acknowledged the challenges of building a better battery but were also confident that overcoming the process hurdles would lead to cost reductions (as high as 40%) and functionality improvements.

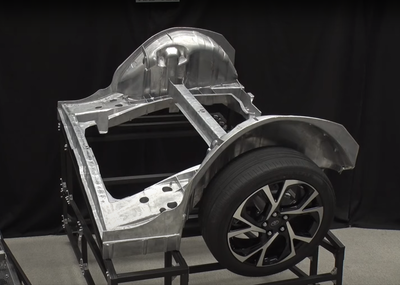

Toyota is also reportedly using high-pressure casting techniques to build its future EVs' components, with a goal of die-casting vehicle frames in just three pieces within four years. Reuters also added that Toyota’s molds can be replaced in as short a time as 20 minutes, a process CleanTechnica says “normally takes up to 24 hours to accomplish.

The leading-edge manufacturing techniques also include an electric vehicle production line that’s described as “self-propelled.” In reality, Toyota vehicles with batteries, motors, and wheels can essentially drive themselves to the location of their next needed component.

With innovation and automation at the forefront, Toyota has a solid foundation to enable it to catch up in a crowded market for EVs. Just how quickly they get there will be dictated by the pace of change.

Source: www.thomasnet.com