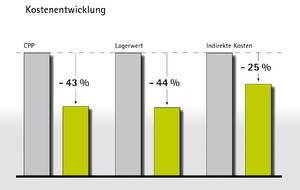

Figure 1: Savings with tool management |

Figure 2: Machined cylinder head |

Significant cost reduction due to tool management

DEUTZ DITER manufactures cylinder heads for one-cylinder to six-cylinder engines in Zafra, Spain. In 2008 MAPAL took over the tool management for cylinder heads with four and six cylinders for the company. A team of five MAPAL employees started with an inventory and analysis. On the basis of this work a series a measures was defined, such as the optimisation of all tools in relation to tool life, machining time, tool fracture and technology. As a consequence it was possible to reduce the costs per workpiece by approx. 30 % and the value of the tool inventory by approx. 28 % within a year. The introduction of the tool dispensing system MAPAL Toolbase EL has made a significant contribution to the reduction of the value of the inventory. By defining minimum, maximum and reorder levels based on realistic replenishment lead times, and by removing superfluous inventory and with the aid of the software function for searching for redundant tools, it was possible to achieve optimal inventory management. Along with these basic tasks, a major part of the challenge was to ensure sustained and continuously optimised smooth communication and the usage of defined processes and procedures.

The success story continues

During the upturn in 2010, cylinder head type 2 was implemented. With the extension of the contract for 3 years at the start of 2011, it was possible to integrate cylinder head type 3 with a production volume of 15,000 pieces. Despite the significant increase in the production volume, the value of the inventory of tools used has been reduced by 44 % from 2008 to 2011 due to an optimised tool inventory. The costs per workpiece also dropped by 43 %. In addition to the process and tool-related optimisation, it was possible to reduce the indirect costs comprising tool procurement costs, tool management expenses, shipping and freight costs, storage costs and interest on the inventory by around 25 %.

The coming challenges

Also under discussion is more intensive collaboration with MAPAL on the re-tooling of existing machine tools including clamping fixtures and NC programs for all new developments. MAPAL offers all the necessary services with its re.tooling service. With experience from a large number of projects, re.tooling is an appropriate supplement to tool management.