Last week, Weijing was able to deliver a set of unique 2-axis grinding machines to a Tunisian foundry and was very proud of it, because the 2-axis grinding machines were chosen for the round parts.

To begin with, the technical director of the Tunisian foundry came to Weijing in January to order a grinding machine to remove residual material from round iron parts: Flywheel, disc brake, clutches. He found that Weijing's 2-axis grinding machine was capable of removing the residual material from round parts, but he was not sure if it was suitable for his parts.

After a few rounds of testing, Weijing recommended them the unique Weijing 2-axis grinding machine with the following explanation:

1, The parts are round and the residual materials are at the same level as the raw castings.

2, The average cycle time is about 0.5 minutes, including loading and unloading.

3, One machine has two grinding stations to grind two parts at the same time.

4, It takes only 35K USD including spare parts for 2 years of operation.

This means they can get two grinders for only 35K USD.

It should be the 33rd grinding machine that Weijing makes for round parts as of 2016.

6 years ago, some foundries found that the normal grinding machines with robot arm mechanism are luxury for machining their round parts. This was because they found that the gates, burrs or parting lines they wanted to remove were almost at the same level on the round part, and if the part could automatically rotate against the wheel, that was enough as they did not need to move the part up or down.

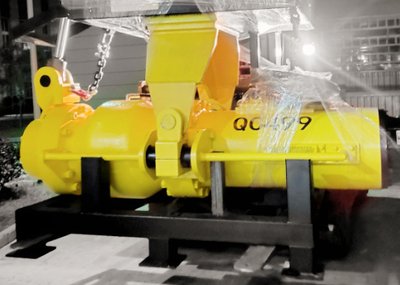

Dedicated grinding machine for round casting

After clarifying the requirements with the foundries, Weijing developed a unique grinding machine for round parts: first, to move the part forward to the wheel; second, to automatically rotate the part against the wheel; third, to move the part back after fettling. No additional costs for extra steps or axes.

Concise, highly efficient and extremely cost-effective.

Market feedback has proven that foundry users are satisfied with the Weijing 2-axis grinder because they have shared and complemented each other.

Weijing strives for the best solution for the end user and an economical and efficient process for the foundries.

What does this grinding machine look like? What is the actual performance?