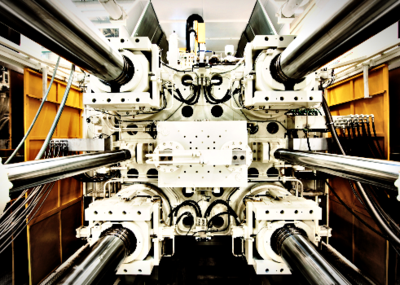

Italpresse Gauss, the Italian leader in fully automated, digitally enabled die casting technology, is set to deliver the first toggle-free two-platen die casting machine with a closing force of 5700t.

The TF 5700 was introduced in 2018 and is currently being made for a premium car manufacturer in Germany.

With its platen size of 3500 x 3500mm the machine is a response to the growing demand for ever larger components and structural parts – particularly in automotive.

Toggle-free (TF) machines generate the closing force hydraulically, whereas those with toggle do this mechanically. This means the toggle-free machine only needs two platens instead of three, which means a smaller footprint.

Italpresse Gauss introduced the TF machine concept in 2005 after developing it fully in-house, including the closing unit. The biggest closing force of a TF to date was 4400 tonnes.

Marco Giegold, Area Sales Manager at Italpresse Gauss: „Lightweight construction and electric vehicles are driving the demand for ever bigger castings – structural components and battery housings, for example. Die casting machine sizes have to keep up with that. Our TF 5700 is the biggest toggle-free machine to date and is ahead of its time digitally, too. The market’s responded very positively to it and we’re getting enquiries from around the world.”

More information on the TF 5700 can be found HERE.