On November 30, 2017, the leading foundry consumable supplier, ASK Chemicals, celebrated the official opening of its new Spanish plant. The company invited customers, suppliers, workers, and local authorities to join an interesting one-day program in the Port of Bilbao (Zierbiena).

In keeping with the motto “Innovative solutions for the foundry industry – a new plant for new challenges”, the company presented its new, modern facilities to its guests and hosted interesting speeches on the latest ASK Chemicals technologies.

Certainly one highlight at the event was Sales Manager Spain Jesús Reina’s speech on “Material properties and process requirements for inorganic core production”. The INOTEC technology has established itself over the past ten years as a productive and alternative core manufacturing procedure in serial casting production processes, especially in the segments of aluminum cylinder heads, crankcases, and suspension parts by low-pressure die casting and gravity casting applications. The odorless and emission-free core production with INOTEC is characterized by very low cleaning and maintenance efforts for machines and tools. Ecological advantages are strongly linked to economic and technological benefits as increased permanent mold availability leads to a general growth in productivity and improved mechanical component strength as permanent mold temperatures are reduced. In order to profitably deploy this technology and its ecological, economic, and technological advantages, expertise and specialized knowledge of materials and processes are required. The lecture to the Spanish audience focused specifically on those material and process requirements that are key to leveraging the full potential of INOTEC.

A joint speech by José Manuel Hernández, Technical Director at PYRSA, and Julián Izaga, Director of Technology and Innovation at IK4-AZTERLAN, shared the interesting showcase of large steel castings. During the development of the gear wheel of an excavator, ASK Chemicals provided its foundry expertise and know-how to develop a specific mini-riser solution for the highest demands in safety, material, technological, and economical requirements.

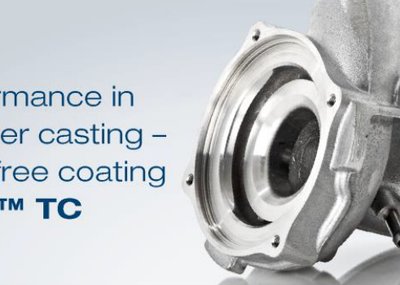

Christian Koch shared with the audience ASK Chemicals’ experience with its MIRATEC TS technology. The guideline VDA 19 (ISO 16232) formulates a very clear requirement for automotive series castings. The residuals in the components are limited by the guideline in order to prolong the maintenance intervals for the engines. Thanks to its self-detaching character, and with good anti-veining and anti-penetration properties, MIRATEC TS is giving the answer to these challenges by reducing the coating residue after pouring to a minimum.

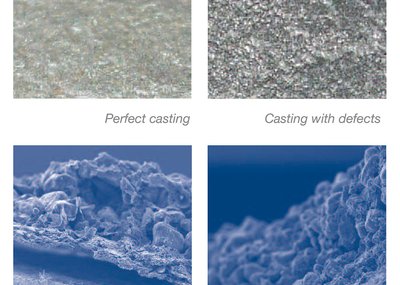

In addition to this, Christian Koch introduced ASK Chemicals’ latest coatings developments for the segment of large casting applications. Here, besides fast-drying, water-based coatings that effectively prevent casting defects, highly productive full mold coatings were presented to the audience. An outlook on future requirements of coatings rounded off the lecture and demonstrated the contribution of coatings to reducing emissions. ASK Chemicals’ patented CELANTOP coating technology absorbs emissions in large casting applications and avoids the need of any further investments in air treatment.

The inauguration event was topped off with a guided tour through the new facilities, where guests got a vivid idea of the new site. “Our new location is designed to fulfill the demanding requirements of the foundry industry. The machinery and testing equipment helps us to ensure the high-quality requirements of our customers – now and in the future,” states Iñigo Zarauz, Managing Director of ASK Chemicals Spain. The new Spanish site of ASK Chemicals accommodates the mini-riser operations as well as coatings production.

Partner

Foundry Corporate News

Topic Chemicals

Topic Plant Technology, Equipment

ASK Chemicals inaugurates its new Spanish plant

Reading time: min

[3]