GOM presents ATOS Triple Scan, the new generation of mobile 3D digitizers

The mobile ATOS Triple Scan 3D digitizer from GOM comes with totally new projection technology (Blue Light Technology) and introduces a 3-in-1 sensor concept for the very first time. The new technology of ATOS Triple Scan offers even greater resolution and accuracy for fine structures and edges, and supplies full-field 3D data for complex components within shortest time. Measurement performance has been significantly improved, especially for shiny surfaces. In combination with the parametric GOM Inspect Professional software package for analysis of measurement data, customers profit now from both faster and traceable quality control.

GOM Inspect Professional: Parametric inspection of 3D data

With its GOM Inspect Professional software package, GOM now moves into the spotlight as an independent software developer. The new software package is designed to do more than evaluate own hardware measurement data only. GOM Inspect Professional is a standalone, process safe, parametric software package that analyzes 3D point clouds from fringe projection scanners, laser scanners, CTs and other 3D measuring systems. Parametric inspection saves vast amounts of time, no matter whether it is based on 2D drawings, 3D CAD data or FTA.

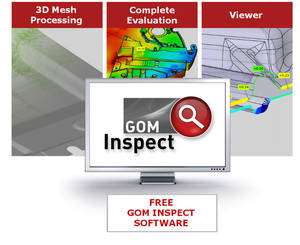

Free software package: GOM Inspect

GOM now provides free of charge access to 3D data processing for everyone with its gratis GOM Inspect software. GOM Inspect is PTB & NIST proven and certified, and is ideal for mesh processing, dimensional analysis of 3D point clouds and can also be used as a 3D viewer. The free version is designed for users who work in RP, CAD/CAM, CAE and CAQ, enabling them to view process and evaluate 3D data from fringe projection or laser scanners, CTs and other 3D measuring systems. GOM Inspect users also benefit from an individual learning concept with tutorials, training videos, sample data and a knowledge database.

GOM turn-key metrology systems are used worldwide by companies from the automotive, aviation and power generation industries, their suppliers and various manufacturers of consumer goods.

GOM´s new Mobile 3D Scanner ATOS Triple Scan sets again a new standard within 3D metrology and quality control

The new generation of mobile 3D digitizers from GOM is a totally new development based on unique technology.

ATOS Triple Scan uses all the viewing angles of the stereo camera system (3-in-1 sensor). It is also based for the very first time on a completely new projection technology. The scanner therefore enables easier, faster and more reliable measurement processes and greatly reduces the number of single scans.

ATOS Triple Scan is equipped with blue light technology, which features extremely long LED service life, minimum heat development and low maintenance. The narrowband blue light enables precise measurements to be carried out independently of environmental lighting conditions.

The new technology in ATOS Triple Scan offers even greater resolution and accuracy for fine structures and edges, and supplies full-field 3D data for complex components within a very short time. Measurement performance has been significantly improved, in particular for shiny surfaces. ATOS Triple Scan cameras, projector and controller are built into a rugged housing. The sensor head is manufactured from shock-resistant CFRP and was developed specifically to meet high application demands in industrial environments.

The professional 3D coordinate measuring system comes in two models. ATOS II Triple Scan offers a resolution of 2 x 5 million pixels, ATOS III Triple Scan a resolution of 2 x 8 million pixels. With preconfigured optics the system is easily adjusted to comply with required accuracies and measuring areas. Changing of measuring volumes takes just a few minutes.

The ATOS 3D Digitizer is a flexible and mobile optical measurement machine. Rather than tactile touch probing of single points, the ATOS system captures the whole surface geometry with a high-resolution and dense point cloud. Compared to tactile metrology no "blind" areas are left since the whole surface is captured completely as point cloud/STL-mesh.

The ATOS 3D digitizer is utilized in pressure die-, investment-, gravity die- and sand casting process chains as a precise, fast and robust solution for Quality Control, Reverse Engineering and Rapid Manufacturing.

Parametric GOM Inspect Professional Software:

Drawing based, CAD based and FTA based analyis at your hand

GOM Inspect Professional is a process-safe, parametric, traceable evaluation software for dimensional analysis of 3D point clouds from white light projection scanners, laser scanners, CTs and other sources.

The new approach of parametric inspection

GOM Inspect Professional software follows a new parametric approach instead of using a macro engine. Every single element knows its path of creation within the software structure. All actions and evaluation steps are completely traceable and interlinked, and can be easily modified or adjusted. A one-button solution updates all dependent elements automatically after changes.

Drawing based inspection

GOM Inspect Professional includes all functions for component inspection based on 2D-drawing. Users can evaluate dimensions such as distances, angles, radii, etc., apply tolerances and also work with traditional tools such as calipers. The GD&T tools allow checking for flatness, parallelism, position, etc. In combination with optical metrology many companies are simplifying their drawings by defining just a few functional dimensions, e.g. via GD&) and setting CAD data, master data or profile tolerances for the rest of the part. Thus the time for first article inspection can be reduced enormously.

CAD based inspection

GOM Inspect Professional offers import of CAD data such as CATIA, Pro/E, UG free of charge. The software allows various alignment strategies (RPS, best-fit, 3-2-1, etc.) within one project. Full surface color deviation plots are immediately available and allow fast understanding of component warpage, shrinkage, spring-back, etc. GOM Inspect Professional includes all state-of-the-art evaluation tools up to complete reporting. The parametric approach allows measurement planning direct on CAD data completely independent from measurement data. This "Teaching By Doing" concept reduces programming time to zero. Thus the workflow is identical for single and multiple part evaluation, saving time and costs.

FTA based inspection

GOM Inspect Professional enables direct import of FTA features attached to CAD data. Using this direct interface with CAD software packages such as CATIA, the quality control process remains completely digital. This helps to avoid user errors which are often introduced during transferring 3D design to 2D drawing or during transferring information from 2D drawing to 3D inspection software. Staying within the digital process chain helps to avoid cost intensive user errors. Connecting CAD design departments with quality control department also helps save valuable time within the PLM chain.

Free GOM Inspect Software for:

Mesh Processing, Inspection and 3D Viewing

GOM introduces the free GOM Inspect software at Control 2011.

The GOM Inspect software package includes enhanced functions for mesh processing as well as for shape and dimension analysis of 3D point clouds and also serves as a 3D viewer - all free of charge.

Complete evaluation tools for analysis of 3D point clouds

GOM Inspect offers all functions for professional shape & dimension inspection of 3D coordinate data. It guides the user from point cloud to inspection report in one software packages.

Polygon mesh generation and processing

GOM Inspect automatically converts point cloud data into high quality 3D mesh data and offers extensive post-processing functionalities such as hole-filling, thinning, smoothing, etc. The GOM Inspect software package is complete independent of any specific hardware.

GOM Inspect Community

The free version is designed for users who view, process and evaluate 3D data from fringe projection or laser scanners, CTs and other sources. The download is highly attractive for CAD/CAM, CAE and CAQ professionals.

Individual Learning Concept

Users of GOM Inspect have access to written step-by-step tutorials and training movies. Also a knowledge database and sample data, are available direct from the software or GOM Website. GOM offers also introduction seminars for small groups of trainees.

Entire process control with optical 3D digitizing

Major benefits for the pattern making and casting industries thanks to full-field 3D metrology

Optical 3D coordinate measuring technology for complete process monitoring

The use of optical metrology can be applied to far more than just the inspection of cast components. Integrating optical metrology systems actually improves process accuracy at virtually all stages of production. It also provides major time and cost benefits and, at the same time, shortens delivery times and reduces the number of reject parts. Many companies concentrate initially on the dimensional validation of cast parts. However, optical metrology supports and accelerates practically all stages from pattern & tool design, molding shop / core-making through to first article reports and optimization of CNC manufacturing. Hence, broad usage of optical metrology throughout the casting process chain improves overall cost-effectiveness.

Validating patterns, tools and forms

Validation of forming contours for patterns, core-making tools, molds and die-casting tools, etc. with optical metrology represents an end-to-end inspection process, which assures pattern & form makers that everything is in order. Compared with tactile measuring procedures, in which only individual points are measured, optical metrology measures the entire surface. In addition, rapid measurements reduce costs and shortens interruptions to the production workflow. For example, the inspection of milling results makes it possible to detect and correct any faults in pattern plates, molding equipment and cores.

Full-surface inspection of cast parts

The casting industry also benefits from complete measurement of cast parts. This process makes it possible to show part deviations from CAD data by color in a report. Thus inspection reports are easy to understand, with the colors also providing information about the corrective measures that are required. This reduces several hundred pages of conventional tabular test reports to a handful of images and functional dimensions. Thus optical metrology gives users an invaluable advantage during development as well as during first article and series inspections.

See you at ![]() GIFA

GIFA

Hall 13 Booth B03

| GOM, Optical Measuring Techniques is a leading manufacturer in "moulding and core making","Pattern and die making","Control systems" and "Measurement and test technology", for further information and contact details click here: GOM, Optical Measuring Techniques |