At the leading international trade fair for casting and foundry technology in Düsseldorf, GOM presents the latest technologies in the field of 3D metrology and inspection. GOM measuring systems are used in sand, pressure die and investment casting processes for continuous quality assurance: from simulation validation and acceleration of tool try-out and first article inspection to production control and CNC machining.

Accelerate production start – Save rework time – Reduce rejects with 3D metrology

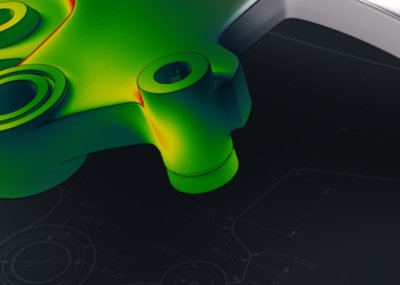

GOM systems enable inspection planning based on CAD data. In pattern, tool and mould making, tools and models are specifically corrected and the fit of mould halves, cores and slides inspected. In the try-out phase, cast parts are checked for shape and dimensional accuracy: component geometry, wall thickness, shrinkage and distortion. Measurement and evaluation are automated for quality control during series production.

GOM Break–Out Sessions (60 min): Casting and Foundry Process Optimization Through 3D Metrology

The 60-minute break-out sessions are aimed at experts from the fields of simulation, design, pattern and model making, tool & mould making, core making, foundry and CNC machining including tasks of quality assurance, production and development. All participants from sand casting, die casting, investment casting and–, gravity die casting manufacturing processes with prototypes or series production can benefit from the break-out session.

Topics GOM Break–Out–Sessions (60 min):

- Geometric validation of patterns, tools, molds and cores

- Slope analysis and verification of milling results

- Provision of warpage, shrinkage and sink marks

- Digital assembly & wall thickness optimization

- Quality control and first article inspection during series production

- Geometric Dimensioning and Tolerancing

- CNC machining and adaptive manufacturing

Dates GOM Break–Out–Sessions (60 min)

Wednesday, June 26 | 11.00 a.m. (English)

• With user experience presentation: Allard-Europe, The Steel and Iron Foundry

Wednesday, June 26 | 2.00 p.m (German)

• With user experience presentation: Krämer + Grebe GmbH & Co. KG

Engineering – Tooling – Casting: 3D Metrology in Product Development

Thursday, June 27 | 11.00 a.m. (English)

• With user experience presentation: Allard-Europe, The Steel and Iron Foundry

Thursday, June 27 | 2.00 p.m. (German)

• With user experience presentation: Krämer + Grebe GmbH & Co. KG

Engineering – Tooling – Casting: 3D Metrology in Product Development

Venue: Hall 10, Room 10.1 A

Krämer + Grebe GmbH & Co. KG

Krämer + Grebe manufactures high-tech foundry tools and complete foundry patterns. These include in particular die-casting moulds, patterns and core molds as well as permanent molds for iron and light metal casting in die -casting, permanent mold casting and sand casting processes. Krämer und Grebe’s special services include process and tool optimization as well as support for maintenance and repair. As one of the market leaders in the development, design and manufacture of molds and tools for demanding castings from prototype to series production, the company is a recognized partner of the international automotive industry and foundries worldwide.

Engineering – Tooling – Casting: 3D Metrology in Product Development

Dieter Winkler (Head of Quality Assurance) and Thomas Achenbach, (Project Manager FEM and CFD Simulation) from Krämer + Grebe in Biedenkopf-Wallau (Germany) report on their many years of practical shop-floor experience with the GOM ATOS 3D measuring system and the GOM Inspect Professional software for 3D data processing in foundries.

GOM Metrology Live (10 min) – Knowledge Transfer to Go

Directly at the booth, GOM experts give 10-minute presentations that provide an introduction to optical 3D metrology for your industry.

Topics GOM Metrology Live (10 min)

- GD&T analysis

- Model and toolmaking

- Mold and core making

- Digital assembly

- Quality control in series production and first article inspection

- CNC machining and adaptive manufacturing

Dates GOM Metrology Live (10 min)

Tuesday, June 25 – at 11:00 a.m. and 2:00 p.m.

Friday, June 28 – at 11:00 a.m. and 2:00 p.m.

Venue: Hall 13, Booth B04