Structural automotive components such as shock towers, longitudinal members, door frames, A-pillars and tailgates have traditionally used sheet metal production. But aluminum die casting can produce a superior, lighter, cost-effective product.

As the automotive industry moves towards lighter and more cost-effective designs, can die casting become the preferred process for structural components? Bühler believes, if the industry pulls together, it can.

Starting points to make die casting more attractive

There are multiple factors which influence the costs of structural components. First of all, the required materials are expensive. Alloys that do not require any further heat treatment and which contain fewer costly elements could reduce the total costs substantially.

Also, there are cost-saving opportunities in the die casting process itself, including the service life of the die, the cycle time, the stability of the production process and the quality of the castings.

Technological advances with high impact

In the development approach Bühler continues to focus on driving costs down.

One important factor on the costs of components is the service life of the die. The path towards a longer service life is clear – a more even thermal management.

Concerning cycle time also the spraying process needs to be considered. It occupies the largest part of the process and is often used to cool the die. An approach to cut down on cycle time therefore is conformal cooling which has already been tested successfully.

Another point impacting the costs of production as well as the cycle time is the control of the cell. A cell management system – a control system that monitors and controls the entire casting cell centrally – helps to substantially increase the uptime of the cell.

Suitable plant technology

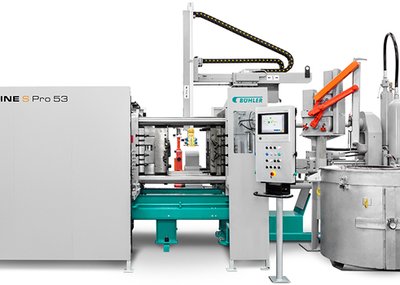

A decisive factor for reliable production of structural components is to have suitable machines and plant technology.

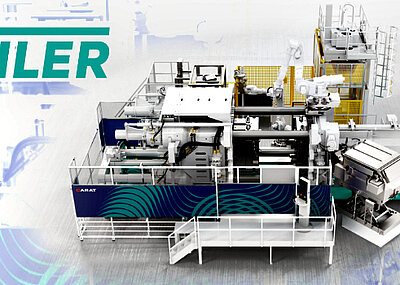

The Bühler Carat has proven to be very effective in this regard. Worldwide, approximately 50 percent of all structural components for the automotive industry are produced on Carat systems. The unique control of the casting process in real time ensures an extraordinarily high degree of reproducibility across the entire casting process.

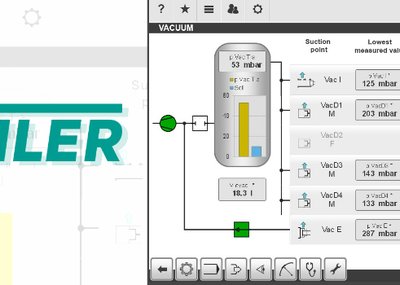

Additionally, for crash-relevant structural components, vacuum technology is essential, as it enables consistent high quality. With the Bühler SmartVac, which is successfully in operation in many applications since its market introduction at GIFA 2015, the vacuum system is directly integrated in the machine control system. Relevant parameters of the vacuum system are recorded in real-time and can be assigned to the corresponding cycle and, therefore, the corresponding component. In addition to the high quality of the components, it also enables full traceability.

An industry-wide approach to make die casting the go-to solution for structural components

As Bühler continues to work on optimizing production processes, reducing cycle time and improving quality within the cell, also upstream and downstream areas need to drive overall efficiency.

If suppliers can help to lower material costs and manufacturers of peripheral devices can work with us to ensure that cell management can be efficiently implemented, it is feasible that die casting can become the method of choice for structural components for many years to come.

Partner

Foundry Corporate News

Topic Pressure Die Casting

Bühler: Tapping into the market potential for structural components

Reading time: min

[2]