One of these is the Schaufler Fischer Group, headquartered in Laichingen. Its subsidiary Schaufler Tooling in particular shows how traditional industry can reposition itself through innovative strength. For over six decades, the company has been manufacturing sophisticated die-casting tools that are used in both classic automotive engineering and electromobility. With locations in Asia and North America, the company is now considered an international leader in its segment.

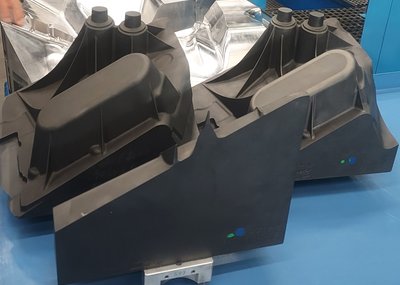

Die casting molds enable extremely diverse component geometries to be created from liquid aluminum – an advantage that is particularly crucial in vehicle production. Whether for combustion engines or electric vehicles, the Laichingen-based company supplies tailor-made special tools for both worlds.

The Schaufler Fischer Group is managed by Siegfried Heinrich and Joachim Schuster, who are largely responsible for the company's direction.

A rapidly growing market segment

In an interview, the company's management explains that a highly dynamic subsystem is currently developing in the field of die-casting molds: giga molds. These particularly large tools enable the production of exceptionally large vehicle components.

What are these parts needed for?

They are mainly found in the underbody of modern electric cars. The company has thus established a stable foothold in a future market. Although general demand is declining, the share of molds for e-components is growing steadily.

Giga molds as growth drivers

These huge tools have become an important source of revenue—and according to Schaufler Tooling, their importance will continue to grow. In addition to mega and giga molds, the company also manufactures molds for other electric mobility components, such as motor housings.

They are also increasingly supplying complete turnkey solutions – an area in which demand is growing rapidly. However, the long delivery times for the massive mold plates remain a challenge, and the company is continuously working to improve this.

Stable through the crisis – and with plans for more staff

Despite the current market situation, there is no shortage of orders. According to the company's management, the focus is now on stable personnel development in the coming year. As a lot of optimization has been carried out in the international branches, investments and new acquisitions were able to be made even during the crisis years.

The group employs a total of around 220 people, around 140 of whom work at its largest site in Laichingen. Thanks to short-time working, the workforce was maintained even during the weak phase at the beginning of 2025; in the meantime, short-time working has almost completely ended. The company even expects moderate job growth in the coming year.

Training to secure the future

Schaufler Tooling continues to place great emphasis on its own young talent. Whether in tool mechanics, commercial professions, or IT, training remains a central component of the company's strategy. Training places were once again awarded this year.

For current and future trainees, the situation is clear: the training places are secure and the prospects are good.