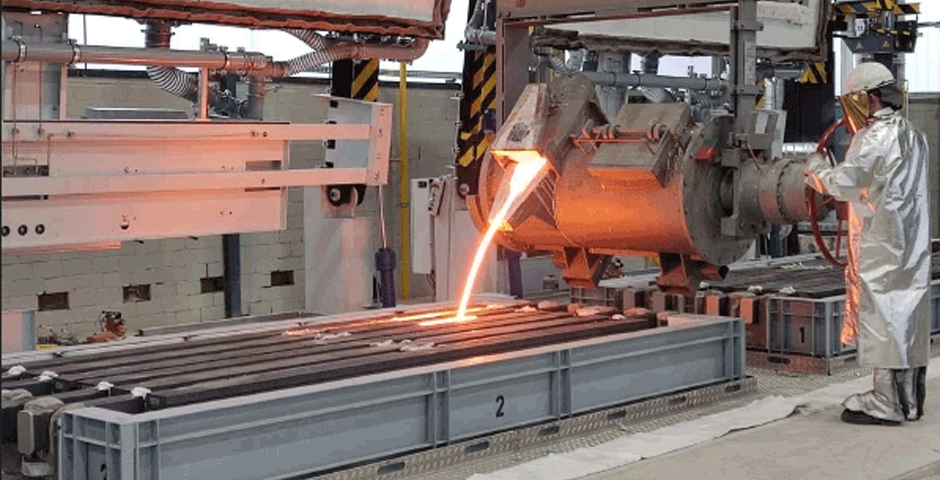

Cathode casting in action

Right on time and on schedule for the fourth Advent, the four new "candles" (four new promeos® furnaces) in the cathode production at TRIMET Aluminium in Essen were burning. A great project "has passed its baptism of fire", says the experienced Trimet project manager, Dr Joachim Heil, with satisfaction.

After the successful assembly and commissioning of the units specially developed for TRIMET for the fabrication of graphite electrodes, the first casting was due. The fact that the eagerly awaited milestone "immediately worked very well" made everyone involved go into the Christmas holidays satisfied and also a little proud.

Proud, among other things, that in the first realization of the overall process consisting of preheating, melting, liquid iron transport and cathode casting, all the wheels immediately meshed as planned. In view of the fact that not only did several new units "start-up" at the same time, but also the newly designed process sequence was operated under real conditions for the first time, this is also proof of how conscientiously and carefully the project teams from TRIMET and promeos® worked together during the development and preparation of the project.

In the course of the overall investment in the new process and the new kilns, the hall infrastructure including supply technology and flue gas system with new chimney was also modernized, which also meant extensive structural measures. An extensive and forward-looking investment that will also greatly benefit the environment.