Background

The Rubtsovsk branch of the company OJSC Altaivagon produces castings for railway truck bogies. One of the more difficult components to manufacture is the bogie side frame, due to the high standards required. When in use, bogie side frames are subject not only to static and dynamic loads, but also to torsional effects associated with the turning motion of the trucks. Dynamic loading is primarily cyclical in nature.

Owing to a serious shortage of side frame components on international markets, technology is now being called for to support the sustainable production of castings capable of complying with strict inspection specifications.

Ceramic foam filters first appeared in the 1970s and have primarily been used for the filtration of cast iron and non-ferrous alloys. Initially used outside Russia, the filters were first introduced to Russia at the beginning of the year 2000. The development of filtration in the casting of steels has not, however, been as simple as that of cast iron and the non-ferrous alloys. Many companies have tested filters, but many production facilities have decided against their use, due to poor results. The main problems encountered have centred on short castings and filter breakdown. This is due to the fact that steels, by contrast to cast iron and non-ferrous alloys, are strongly contaminated by the products of oxidation and possess low slag fluidity. These difficulties have limited adoption of filters over the last ten years. During this period, there have been developments in the adaptive gating systems for the filters and issues relating to steel refinement have been solved.

In relation to the purity of the metal castings, the first step is to establish the source of any incoming non-metallic inclusions. These can be divided into two main groups – endogenous inclusions and exogenous inclusions. Exogenous inclusions are foreign bodies, typically sand particles, mould and lining materials and furnace and ladle slag. Indigenous inclusions are the products of chemical oxidation reactions, which take place during the production and pouring of the metal. Indigenous inclusions are represented by silicates, oxides, nitrides, sulphides and their compounds [1].

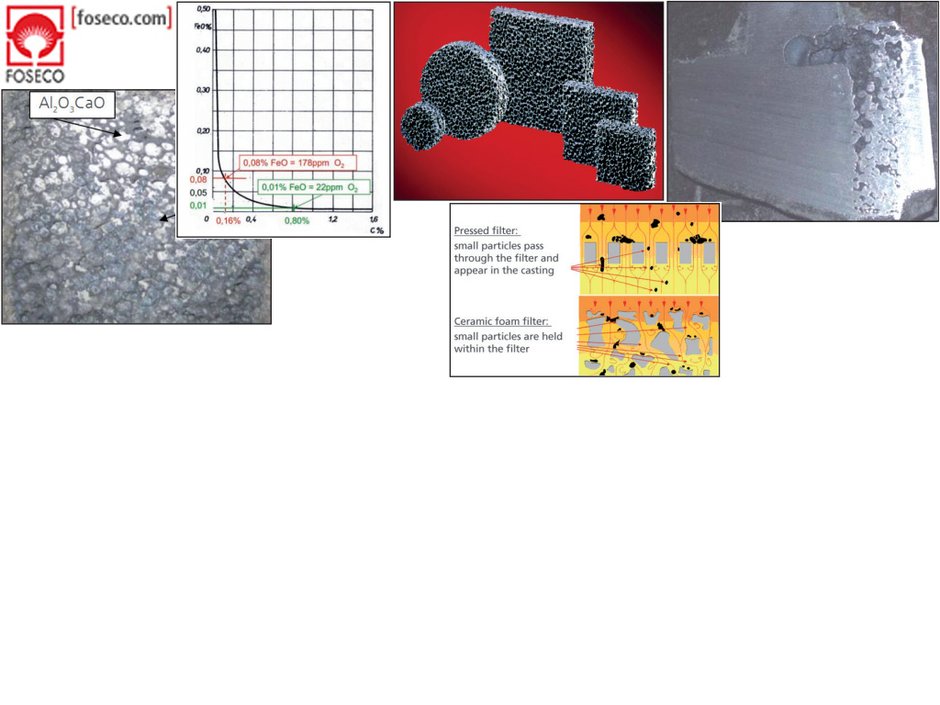

The reducing agent primarily used in steel casting is aluminium, which has a strong affinity for oxygen and reduces iron from its oxide to give aluminium oxide. In the iron oxide solubility diagram (Figure 1), it can be seen that the lower the carbon content of a steel, the higher its iron oxide solubility. So, reactions involving 0.8% carbon steel require 23 grams/tonne of aluminium and produce 45 grams of aluminium oxide, whereas those involving 0.16% carbon steel require a minimum of 200 grams of aluminium and produce 376 grams of aluminium oxide. It follows that the lower the carbon content of the steel, the greater the amount of reducing agent required and the greater the amount of oxidation products formed [2].

It should be noted, that the process of secondary oxidation and consequent reduction giving rise to the formation of inclusions takes place in the mould cavity during the pouring of the melt. The intensity of this process is dependent upon the metal flow in the mould cavity. The flow is dictated by the gating system configuration and the point of delivery of the metal into the casting.

Research undertaken in the USA at the end of the 1980s at 14 casting facilities specialising in the production of carbon and low-alloy steels [1] focused on the testing of 500 specimens cut from castings. In 83% of the specimens tested, the non-metallic macro-inclusions found in the castings were the products of secondary oxidation, i.e. oxidation of the metal at the time of its pouring into the mould.

The inclusions detected had magnitudes of up to 10mm. The results suggest that in order to reduce the incidence of non-metallic inclusions, it is first of all necessary to prevent or minimise the process of secondary oxidation of the metal in the mould. Provided the associated gating system is properly constructed, a filter is able to stop the passage of non-metallic inclusions coming from the ladle and inhibit the formation of oxide inclusions in the mould.

The application and benefi t of filters

Foseco STELEX* PrO (Figure 2) is a range of carbon-bonded ceramic-foam filters. These filters have the following special physical properties: low heat storage capacity, high durability in the heated state, high flame resistance, low thermal expansion and tolerance to thermal shock. These special properties make the filters suitable for use in the casting of low-carbon steels.

In order to use the filter in gating systems, Foseco’s specialists have developed an optimum gating system, which ensures that filter loading is optimised during the pouring of the melt. The gating system also minimises flow turbulence and, consequently, reduces oxidation of the steel in the mould cavity – a fact confirmed by the findings of the MAGMA* programme.

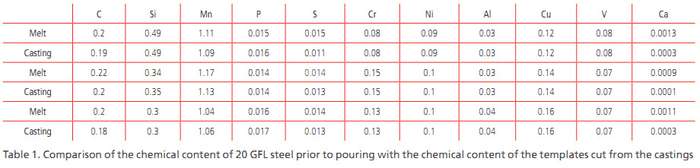

The results of the experimental work undertaken demonstrate how the chemical make-up of the casting is altered. A selection of tests was carried out on 3 melts poured from bottom-pour ladles to determine their chemical content. The chemical make-up of the castings was determined on templates cut from a journal box hatch. Comparison of the results obtained from the chemical analysis suggests that no carbonisation effects are present when using a filter (Table 1). The tests undertaken demonstrate a slight reduction in the carbon content of the casting of 0.01 – 0.02%.

As a result of the molten metal flowing through the filter, a 3- to 9-fold reduction in the Ca content of the casting is observed, when compared with the results of the chemical analysis of the melt. A possible explanation is that, during the process of filtration, calcium oxide inclusions (the products of deoxidation) are held on the surface of the filter (Figure 3). Only “active” calcium flows through into the mould.

The alumino-silicates seldom encountered in melts under normal circumstances are oval in shape and angular in character. After filtration, however, these inclusions took on a spherical form (Figure 7). At significantly low calcium content, therefore, an improvement in the shape of the non-metallic inclusions identified in the castings was evident. This effect may be explained by the fact that filtration significantly reduces the number of indigenous inclusions, whilst reductions in the turbulence of the flow following filtration reduces secondary oxidation in the mould. It follows that, instead of undergoing repeat deoxidation in the mould cavity, active calcium remains in solution and assists in the formation of globules.

It has been established that the number of oxide and sand inclusions getting through from the gating system (Figures 4 and 6) is reduced when using the filters in comparison with the use of a pressed filter (Figure 5). It is possible that the purging of non-metallic inclusions from the melt is linked with the large surface area of the filter.

Elongated sulphide inclusions were only encountered in one test case (Figure 8).

Globule-shaped non-metallic oxides were found dispersed in 15 out of the 100 photographic field views taken of the templates cut from the test castings (Figure 6). As regards the number and distribution of non-metallic inclusions and in comparison with melts under normal conditions, the application of filters appears to improve the quality of the steel.

A comparison of the earlier metallo-graphic analyses of melts under normal conditions with the test melts poured in the gating system fitted with the STELEX PrO filters, showed that use of the filters brought about an increase in non-metallic inclusion removal of 35 % (Figures 6, 7 and 8).

Conclusions

- The application of STELEX PrO filters is shown to be an effective means of combating melt flow turbulence in gating systems and inhibiting the processes leading to mould erosion. As a consequence, the incidence of slag and sand inclusions in the resulting castings is also reduced.

- The use of filters in gating systems brings about reductions in the number of non-metallic inclusions caused by secondary oxidation in the mould at the time of pouring of the metal.

- Steel castings poured under application of STELEX PrO filters demonstrate increased levels of purity, due to the removal of non-metallic sulphide, oxide and alumino-silicate inclusions.

- Filtration of the steel promotes the formation of globular-shaped alumino-silicates which, in normal castings, are mostly encountered in an elongated, elliptical form.

- The effective introduction of filtration may require multi-stage preparation including the development of specially-constructed gating systems. Improved melt and pouring procedures may compliment the performance of filters.

References

- Svoboda J.M. et al. Trans. AFS 95 187-202 (1987)

- Svalov N.V. “The filtration of large steel castings”, report to “Foundry Concilium No.5”, 2011.

- Brown, John R. “Foseco Ferrous Foundryman’s Handbook”, 2000